SPECIFICATIONS

| Model | Unit | ZPLF060 | ZPLF090 | ZPLF120 | Ratio | Stage | |||

| Rated output torque | N.m | 16.5 | 60 | 148 | 3 | 1 | |||

| 27 | 86 | 222 | 4 | ||||||

| 27 | 94.5 | 235 | 5 | ||||||

| 19.5 | 64 | 158 | 7 | ||||||

| 8.5 | 39.5 | 93 | 10 | ||||||

| 96 | 250 | 12 | 2 | ||||||

| 96 | 250 | 15 | |||||||

| 30 | 96 | 250 | 16 | ||||||

| 30 | 96 | 250 | 20 | ||||||

| 33 | 105.5 | 264 | 25 | ||||||

| 30 | 96 | 250 | 28 | ||||||

| 33 | 105.5 | 264 | 35 | ||||||

| 30 | 96 | 250 | 40 | ||||||

| 33 | 105.5 | 264 | 50 | ||||||

| 21.5 | 71.5 | 177 | 70 | ||||||

| 37.5 | 120 | 310 | 64 | 3 | |||||

| 37.5 | 120 | 310 | 80 | ||||||

| 37.5 | 120 | 310 | 100 | ||||||

| 41.0 | 132.5 | 329 | 125 | ||||||

| 37.5 | 120 | 310 | 140 | ||||||

| 41.0 | 132.5 | 329 | 175 | ||||||

| 37.5 | 120 | 310 | 200 | ||||||

| 41.0 | 132.5 | 329 | 250 | ||||||

| 37.5 | 120 | 310 | 280 | ||||||

| 41.0 | 132.5 | 329 | 350 | ||||||

| Emergency stop torque | N.m | 2 times Rated output torque | |||||||

| Norminal input speed | rmp | 3000 | 3000 | 2000 | |||||

| Maximum input speed | rmp | 6000 | 6000 | 3500 | |||||

| Maximum radial force | N | 170 | 1020 | 2230 | |||||

| Maximum axial force | N | 120 | 850 | 1550 | |||||

| Efficiency | % | Single [97%] | Double [95%] | ||||||

| Average lifetime | h | 20000 | |||||||

| Weight | kg | 2.2 | 4.7 | 11.5 | 1 | ||||

| 2.5 | 5.3 | 13.5 | 2 | ||||||

| 2.8 | 5.9 | 15.7 | 3 | ||||||

| Moment of inertia | kgcm2 | 0.107 | 0.4 | 1.65 | 3 | 1 | |||

| 0.094 | 0.309 | 1.22 | 4 | ||||||

| 0.092 | 0.291 | 1.15 | 5 | ||||||

| 0.091 | 0.285 | 1.13 | 7 | ||||||

| 0.091 | 0.283 | 1.11 | 10 | ||||||

| / | 0.4 | 1.65 | 12 | 2 | |||||

| / | 0.309 | 1.65 | 15 | ||||||

| 0.094 | 0.291 | 1.22 | 16 | ||||||

| 0.092 | 0.291 | 1.15 | 20 | ||||||

| 0.092 | 0.291 | 1.15 | 25 | ||||||

| 0.091 | 0.285 | 1.13 | 28 | ||||||

| 0.091 | 0.285 | 1.13 | 35 | ||||||

| 0.091 | 0.2835 | 1.11 | 40 | ||||||

| 0.091 | 0.283 | 1.11 | 50 | ||||||

| 0.091 | 0.283 | 1.11 | 70 | ||||||

| 0.092 | 0.291 | 1.15 | 64 | 3 | |||||

| 0.092 | 0.291 | 1.15 | 80 | ||||||

| 0.092 | 0.291 | 1.15 | 100 | ||||||

| 0.092 | 0.291 | 1.15 | 125 | ||||||

| 0.091 | 0.291 | 1.13 | 140 | ||||||

| 0.091 | 0.291 | 1.13 | 175 | ||||||

| 0.091 | 0.283 | 1.11 | 200 | ||||||

| 0.091 | 0.283 | 1.11 | 250 | ||||||

| 0.091 | 0.283 | 1.11 | 280 | ||||||

| 0.091 | 0.283 | 1.11 | 350 | ||||||

| Noise | dB | 60 | 65 | 68 | |||||

| Lubricating | Synthetic grease lubrication | ||||||||

| levels of protection | IP65 | ||||||||

Product Display

Product Feature

High Efficiency

The ZPLF Series Reducer offers superior transmission efficiency, ensuring optimal performance and energy savings.

Compact Design

Designed with a compact structure, making it easy to integrate into various mechanical systems.

Low Noise Operation

Operates with minimal noise, providing a quiet working environment suitable for various applications.

Durable Construction

Constructed from high-quality materials, ensuring durability and long-lasting performance in demanding environments.

High Torque Output

Provides a high torque output, making it suitable for applications requiring significant force and power.

Precision Engineering

Engineered with precision to ensure accurate and reliable transmission of power.

Easy Installation and Maintenance

Designed for easy installation and maintenance, reducing downtime and enhancing operational efficiency.

Product Applications

Industrial Automation

Ideal for industrial automation systems, providing reliable power transmission for various automated processes.

Robotics

Suitable for robotic applications, offering precise and efficient movement control for robotic arms and machinery.

Conveyor Systems

Perfect for conveyor systems, ensuring smooth and consistent movement of materials.

Packaging Machinery

Applicable in packaging machinery, enhancing the efficiency and reliability of packaging processes.

Textile Machinery

Used in textile machinery, providing precise and efficient operation for fabric processing and manufacturing.

CNC Machines

Ideal for CNC machines, ensuring accurate and reliable transmission of power for various machining tasks.

Medical Equipment

Suitable for medical equipment, offering precise and reliable operation for various medical applications.

Related Products

Videos

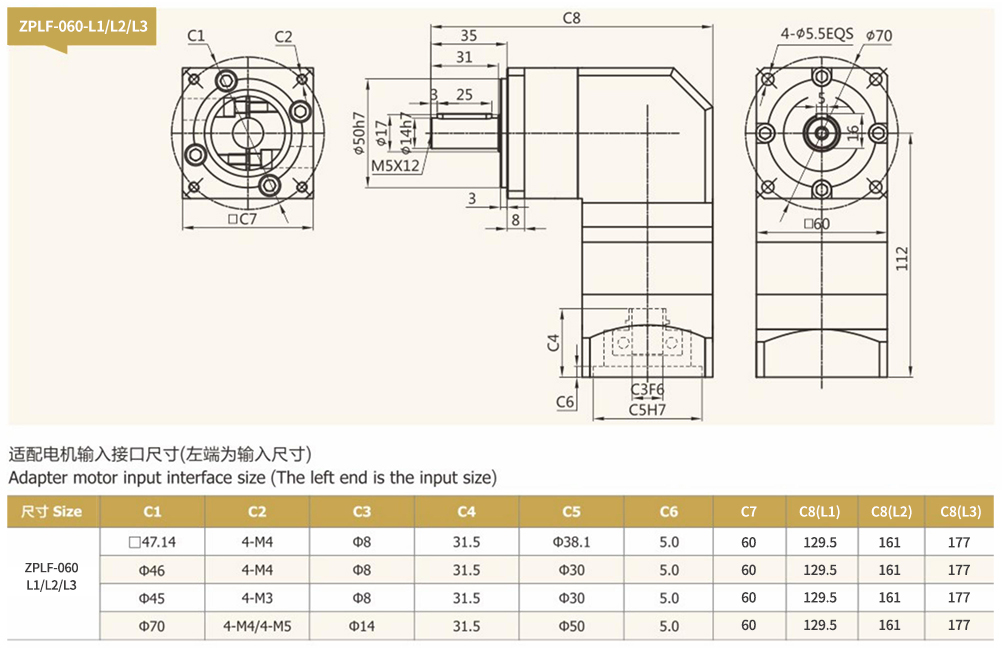

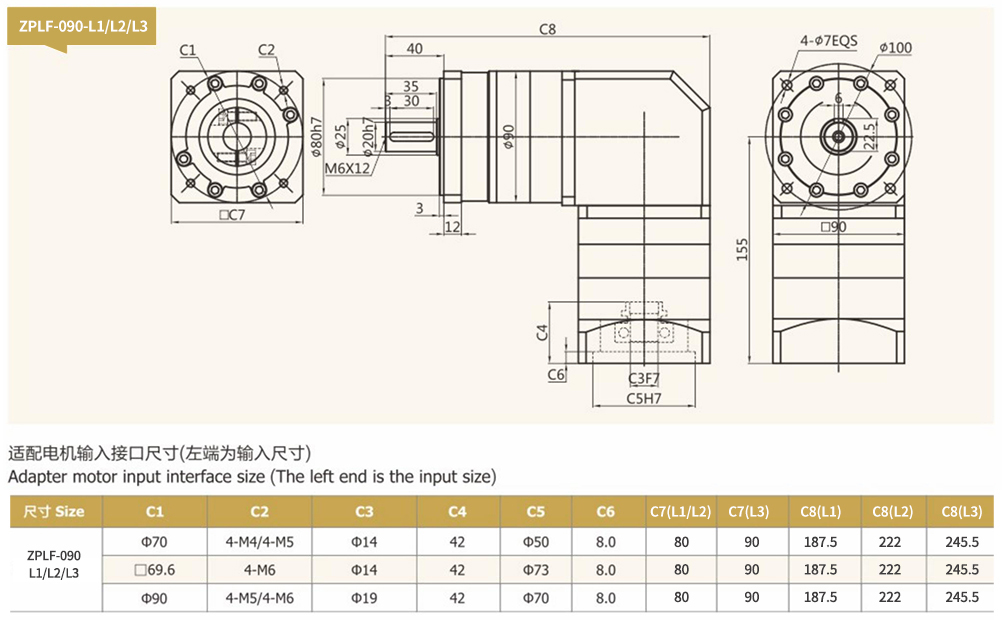

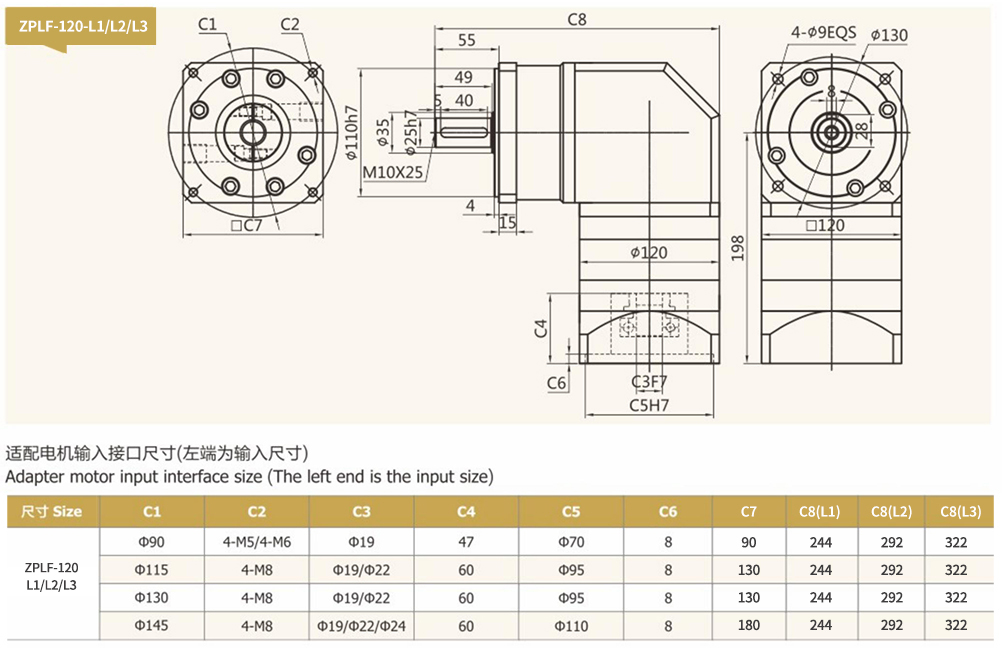

DIMENSIONS

Technical Documents Downloads

| File Name | Size | Download |

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00