ZAF Series Reducer

$

The ZAF Series Reducer is constructed from a robust steel body with long-lasting bronze alloy gearing, providing consistent and reliable operation. Its efficiency rating of up to 95% offers reduced power consumption and improved energy savings. This reliable and efficient reducer is built to last in tough industrial and commercial applications.

SPECIFICATIONS

| Model | Unit | ZAF060 | ZAF090 | ZAF115 | ZAF140 | Ratio | Stage |

| Rated output torque | N.m | 18 | 50 | 120 | 240 | 3 | 1 |

| 27 | 75 | 180 | 360 | 4 | |||

| 27 | 75 | 180 | 360 | 5 | |||

| 27 | 75 | 180 | 360 | 7 | |||

| 18 | 50 | 120 | 240 | 10 | |||

| 35 | 90 | 180 | 450 | 15 | 2 | ||

| 37 | 96 | 230 | 450 | 16 | |||

| 37 | 96 | 230 | 564 | 20 | |||

| 37 | 96 | 255 | 585 | 25 | |||

| 37 | 96 | 230 | 564 | 28 | |||

| 27 | 87 | 180 | 360 | 30 | |||

| 37 | 96 | 255 | 585 | 35 | |||

| 37 | 96 | 230 | 564 | 40 | |||

| 37 | 96 | 255 | 585 | 50 | |||

| 27 | 87 | 180 | 360 | 70 | |||

| 18 | 50 | 120 | 240 | 100 | |||

| Emergency stop torque | N.m | 3 times Rated output torque | |||||

| Norminal input speed | rmp | 3000 | 3000 | 3000 | 2000 | ||

| Maximum input speed | rmp | 6000 | 6000 | 6000 | 3500 | ||

| Maximum radial force | N | 1200 | 2400 | 4300 | 9100 | ||

| Maximum axial force | N | 1100 | 2200 | 3900 | 8200 | ||

| Efficiency | % | Single [97%] | Double [95%] | ||||

| Average lifetime | h | 20000 | |||||

| Weight | kg | 1.4 | 3.7 | 8 | 16 | 1 | |

| 1.6 | 4.2 | 8.9 | 17 | 2 | |||

| Moment of inertia | kgcm2 | 0.16 | 0.61 | 3.25 | 12.31 | 3 | 1 |

| 0.14 | 0.48 | 2.74 | 7.54 | 4 | |||

| 0.13 | 0.47 | 2.71 | 7.42 | 5 | |||

| 0.13 | 0.47 | 2.62 | 7.25 | 7 | |||

| 0.13 | 0.44 | 2.57 | 7.14 | 10 | |||

| 0.127 | 0.72 | 2.56 | 12.35 | 15 | 2 | ||

| 0.088 | 0.5 | 1.75 | 7.47 | 16 | |||

| 0.075 | 0.44 | 1.5 | 6.65 | 20 | |||

| 0.075 | 0.44 | 1.49 | 5.81 | 25 | |||

| 0.064 | 0.39 | 1.3 | 6.34 | 28 | |||

| 0.064 | 0.39 | 1.3 | 6.34 | 30 | |||

| 0.064 | 0.39 | 1.3 | 6.34 | 35 | |||

| 0.064 | 0.39 | 1.3 | 4.08 | 50 | |||

| 0.075 | 0.39 | 1.5 | 7.5 | 63 | |||

| 0.075 | 0.39 | 1.5 | 7.5 | 70 | |||

| 0.075 | 0.39 | 1.5 | 7.5 | 100 | |||

| Backlash | arcmin | ≤5 | ≤5 | ≤5 | ≤5 | Precise[1] | |

| ≤10 | ≤10 | ≤10 | ≤10 | Standard[1] | |||

| ≤7 | ≤7 | ≤7 | ≤7 | Precise[2] | |||

| ≤12 | ≤12 | ≤12 | ≤12 | Standard[2] | |||

| Torsional rigidity | N.m/arc min | 7 | 14 | 25 | 50 | ||

| Noise | dB | 65 | 65 | 70 | 75 | ||

| lubricating | Synthetic grease lubrication | ||||||

| levels of protection | IP65 | ||||||

Product Display

Product Feature

- Helical gear transmission, carburizing and quenching treatment, tooth profile modification treatment, to ensure low noise and smooth operation. The bearing capacity is 20% higher than that of straight teeth.

- Integral output shaft and bearing support at both ends of planetary wheel to achieve high precision and strength.

- The backhaul clearance is small, and the precision single stage can achieve less than 5 arcmin.

Related Products

Videos

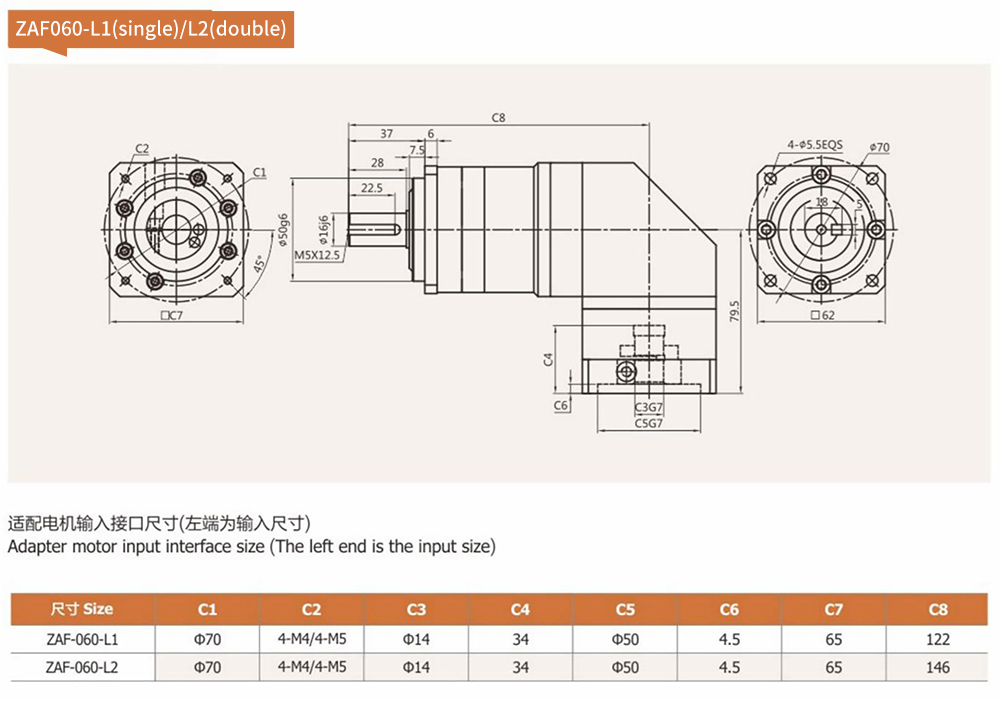

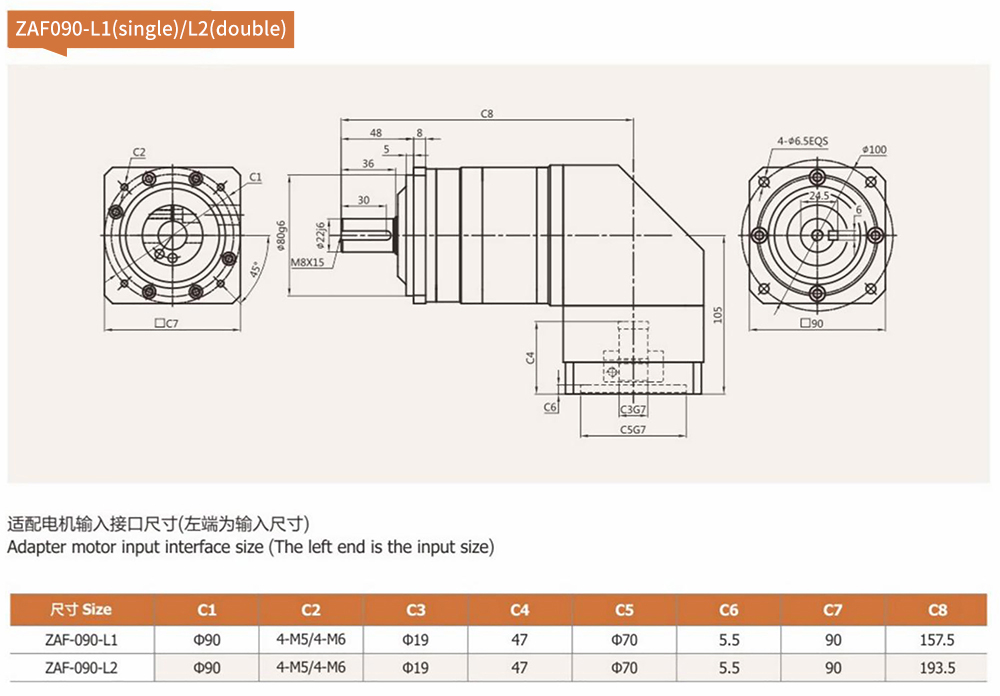

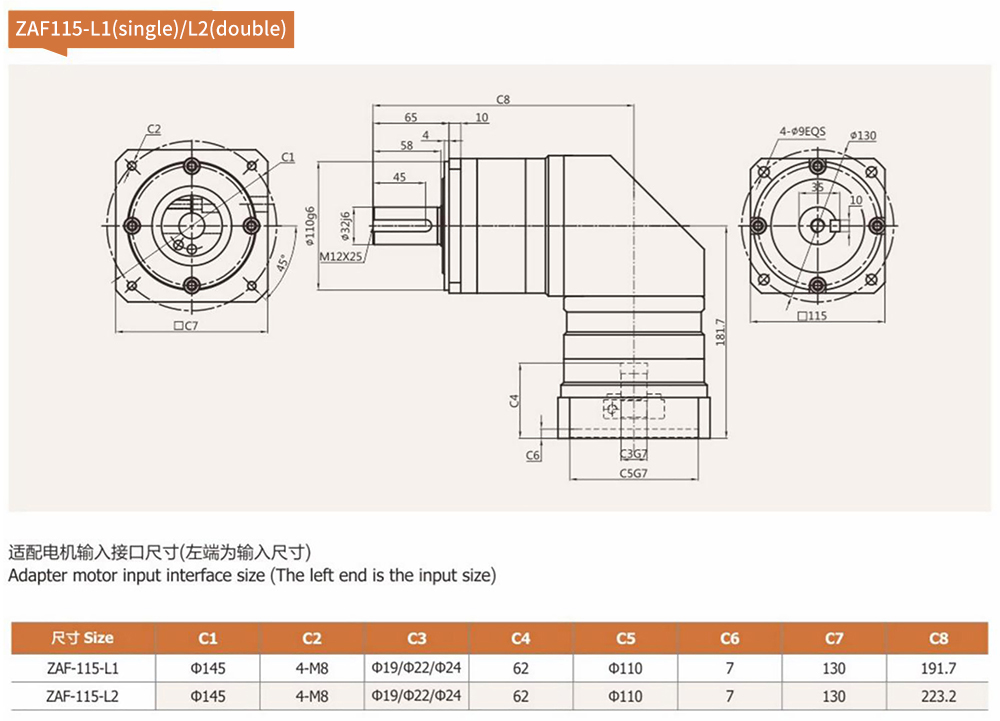

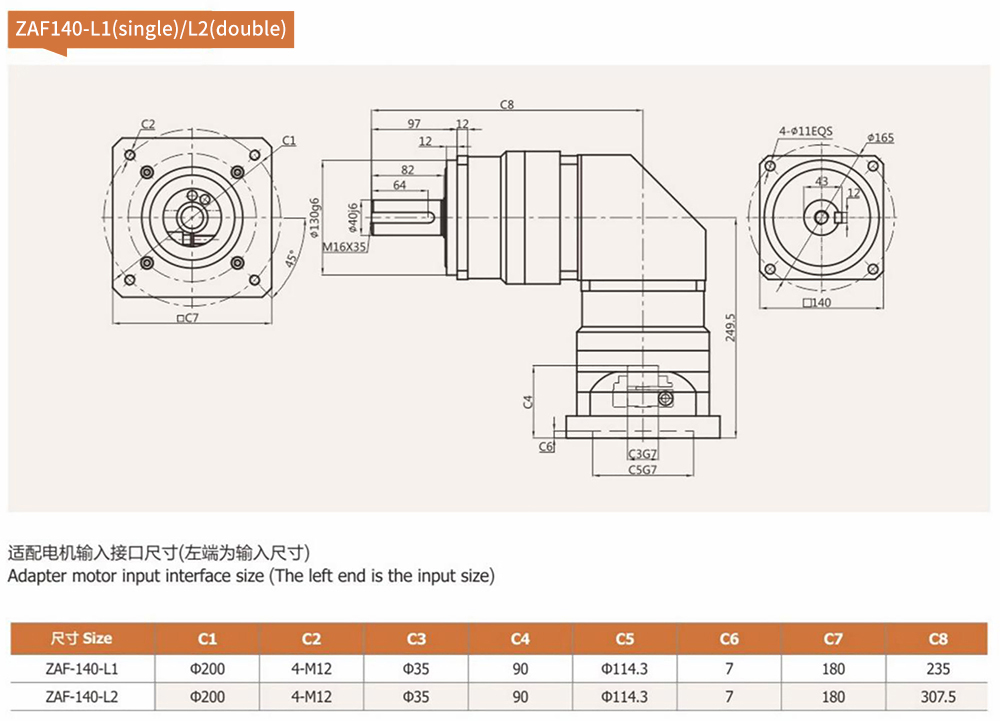

DIMENSIONS

Technical Documents Downloads

| File Name | Size | Download |

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00