Small 6W AC Gear Motor with Speed Controller

$16.00-$317.00

The Small 6W AC Gear Motor with Speed Controller is ideal for applications where accuracy and precision are a must. The motor offers adjustable speed control and is capable of producing 6W of power, perfect for handling mini-sized projects. It runs on either AC or DC power for versatile performance. Perfect for robotics, automation, and other mechanical engineering projects.

SPECIFICATIONS

| Motor Type Lead Wire Type |

Output power W |

Voltage V |

Frequency Hz |

Current A |

Starting torque mN.m |

Rated tourque mN.m |

Rated speed r/min |

Capacitor μF |

|

| Pinion Shaft | Round Shaft | ||||||||

| 2RK6GN-A | 2RK6A-A | 6 | 1ph100 | 50 | 0.265 | 60 | 48 | 1200 | 4 |

| 2RK6GN-A | 2RK6A-A | 6 | 1ph100 | 60 | 0.232 | 55 | 40 | 1450 | 4 |

| 2RK6GN-E | 2RK6A-E | 6 | 1ph110 | 60 | 0.185 | 45 | 40 | 1450 | 2.5 |

| 2RK6GN-E | 2RK6A-E | 6 | 1ph120 | 60 | 0.2 | 45 | 40 | 1450 | 2.5 |

| 2RK6GN-C | 2RK6A-C | 6 | 1ph220 | 50 | 0.145 | 55 | 48 | 1200 | 1 |

| 2RK6GN-C | 2RK6A-C | 6 | 1ph230 | 50 | 0.15 | 55 | 48 | 1200 | 1 |

| 2RK6GN-H | 2RK6A-H | 6 | 1ph220 | 60 | 0.165 | 60 | 40 | 1450 | 1 |

| 2RK6GN-H | 2RK6A-H | 6 | 1ph230 | 60 | 0.17 | 60 | 40 | 1450 | 1 |

| Type Motor/Gearhead |

Gear Ratio | 3 | 3.6 | 5 | 6 | 7.5 | 9 | 12.5 | 15 | 18 | 25 | 30 | 36 | 50 | 60 | 75 | 90 | 100 | 120 | 150 | 180 | 200 | |

| Speed r/min |

50Hz | 500 | 417 | 300 | 250 | 200 | 166 | 120 | 100 | 83 | 60 | 50 | 41 | 30 | 25 | 20 | 16 | 15 | 12.5 | 10 | 8.3 | 7.5 | / |

| 60Hz | 600 | 500 | 360 | 300 | 240 | 200 | 144 | 120 | 100 | 72 | 60 | 50 | 36 | 30 | 24 | 20 | 18 | 15 | 12 | 10 | 9 | / | |

| 2RK6GN-A 2RK6GN-E 2RK6GN-C 2RK6GN-H |

2GN K | 50Hz | 0.12 | 0.14 | 0.19 | 0.23 | 0.29 | 0.35 | 0.49 | 0.58 | 0.7 | 0.88 | 1.1 | 1.3 | 1.6 | 1.9 | 2.4 | 2.9 | 3 | 3 | 3 | 3 | 3 |

| 2RK6GN-A 2RK6GN-E 2RK6GN-C 2RK6GN-H |

2GN K | 50Hz | 1.22 | 1.43 | 1.94 | 2.35 | 2.96 | 3.57 | 5 | 5.92 | 7.14 | 8.98 | 11.2 | 13.3 | 16.3 | 19.4 | 24.5 | 29.6 | 30 | 30 | 30 | 30 | 30 |

| 2RK6GN-A 2RK6GN-E 2RK6GN-C 2RK6GN-H |

2GN K | 60Hz | 0.1 | 0.12 | 0.16 | 0.19 | 0.24 | 0.29 | 0.41 | 0.49 | 0.58 | 0.73 | 0.88 | 1.1 | 1.3 | 1.6 | 2 | 2.4 | 2.6 | 3 | 3 | 3 | 3 |

| 2RK6GN-A 2RK6GN-E 2RK6GN-C 2RK6GN-H |

2GN K | 60Hz | 1.02 | 1.22 | 1.63 | 1.94 | 2.45 | 2.96 | 4.18 | 5 | 5.92 | 7.45 | 8.98 | 11.2 | 13.3 | 16.3 | 20.4 | 24.5 | 26.5 | 30 | 30 | 30 | 30 |

Product Display

Reversible motors have an included basic brake that allows them to stop and change direction in a reasonable amount of time, making them the ideal choice for situations where the motor has to change direction regularly. Reversible motors are available in power ranges from 6W to 120W, and users may choose a gearbox with a parallel shaft to lower output speed and increase torque.

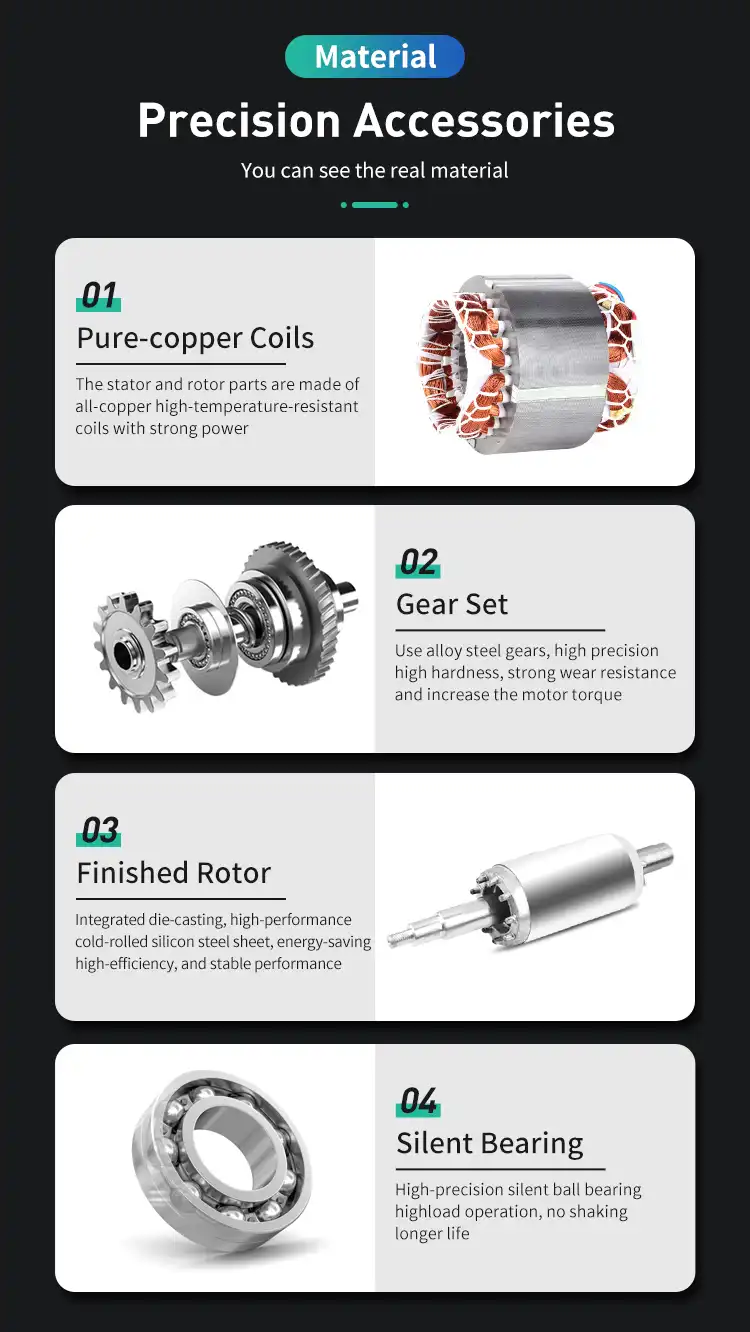

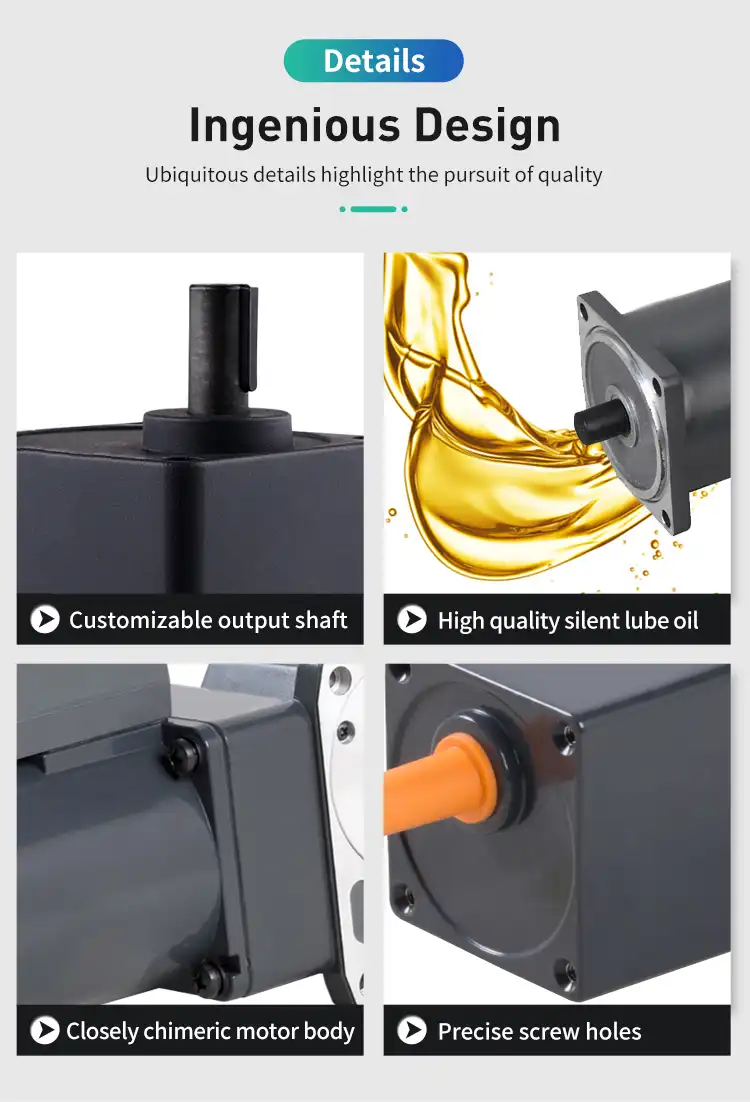

Product Feature

Compact and Efficient Design

Boasting high efficiency in a compact form, this 6W motor saves valuable space while delivering the requisite power for a variety of tasks.

Reliable with Long Service Life

Our motor is constructed for longevity, ensuring consistent and reliable performance over extended periods.

High Torque at Low Speed

Even at reduced speeds, the motor maintains a powerful torque, making it suitable for applications where slow and strong movement is key.

Excellent Overload Capacity

This motor can withstand high levels of overload without compromising its performance or integrity, safeguarding your operations.

Optimal Performance

Engineered for outstanding efficiency and effectiveness, our motor delivers optimal performance across applications.

Energy-Efficient Operation

Low energy consumption is at the heart of this motor's design, reducing operating costs while maintaining a high level of efficiency.

Versatile Application Range

The motor's capabilities make it ideal for a wide range of applications, from home automation to industrial machinery.

Product Applications

Smart Home Devices

Perfect for smart home auto-assistant devices that require the flexibility of reversing directions with regularity and precise control.

Sealing Machines

A reliable pick for tea bag and drink cup sealing machines where consistent torque and controlled sealing speed are necessary.

Automated Production Equipment

The motor's efficiency, robust torque, and reliability make it a solid choice for various automated production lines.

Medical and Laboratory Instruments

With controlled velocity, this motor is excellent for sensitive applications in medical and lab instruments that require exact movement.

Hobby and DIY Projects

The motor's compact size and effective operation align well with hobbyist and DIY projects that require a small yet powerful motor.

Related Products

Videos

DIMENSIONS

Technical Documents Downloads

| File Name | Size | Download |

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00