90W 1phase AC Gear Motor with Terminal Box

$43.00-$49.00

This 90W 1phase AC Gear Motor with Terminal Box boasts an impressive level of power and efficiency, providing reliable performance under varying conditions. It features a low-noise design that makes it ideal for applications requiring quiet operation. Plus, the built-in terminal box makes wiring and connection simple and secure.

SPECIFICATIONS

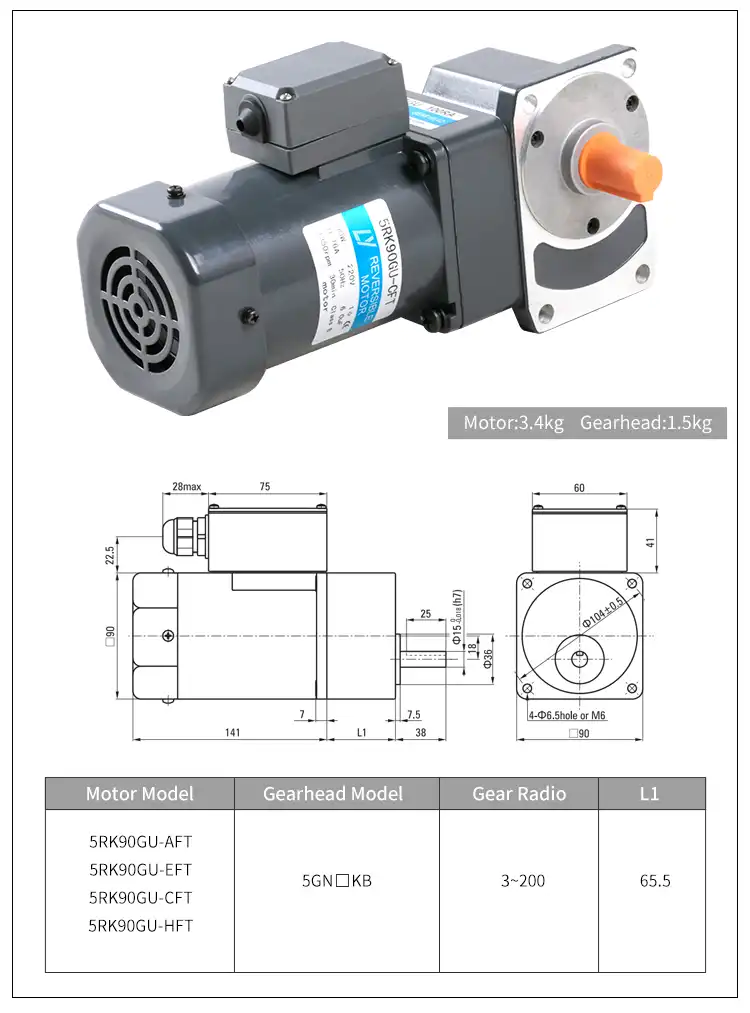

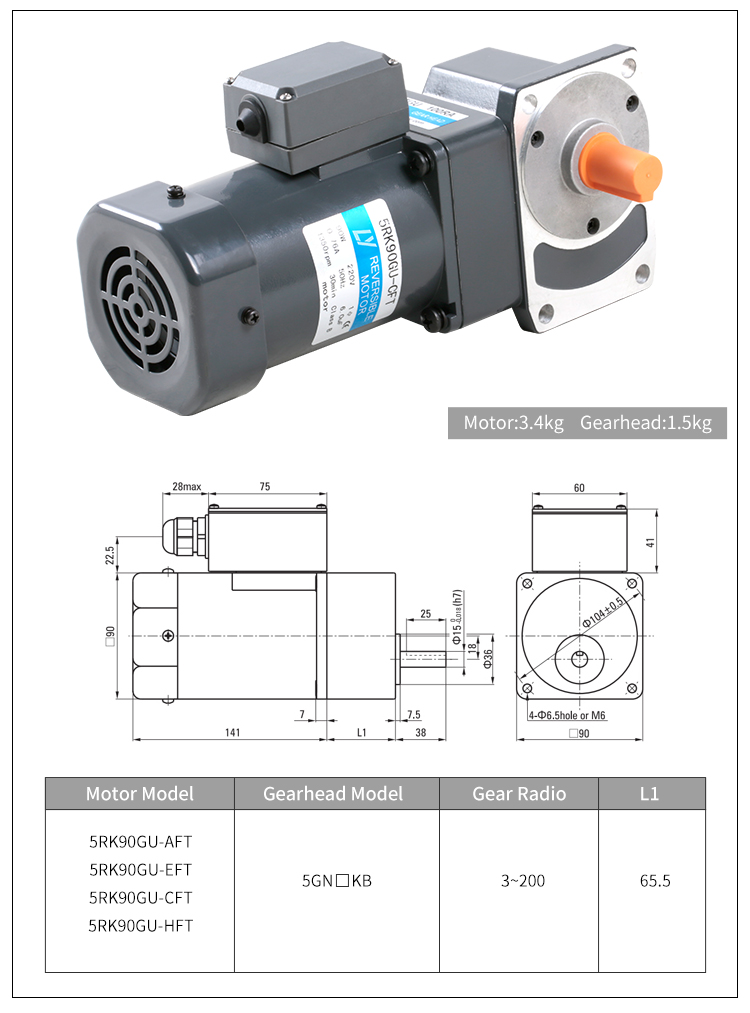

| Model Type Above:gearbox below in():round shaft |

Output power W |

Voltage V |

Frequency Hz |

Current A |

Starting torque mN.m |

Rated tourque mN.m |

Rated speed r/min |

Capacitor μF |

|

| Lead Wire Type | Terminal Box Type | ||||||||

| 5RK90GU-AF | 5RK90GU-AFT | 90 | 1ph100 | 50 | 1.78 | 470 | 700 | 1250 | 30 |

| (5RK90A-AF) | (5RK90A-AFT) | 90 | 1ph100 | 60 | 2.35 | 470 | 570 | 1550 | 30 |

| 5RK90GU-EF | 5RK90GU-EFT | 90 | 1ph110 | 60 | 1.72 | 700 | 570 | 1550 | 25 |

| (5RK90A-EF) | (5RK90A-EFT) | 90 | 1ph120 | 60 | 1.72 | 570 | 570 | 1550 | 25 |

| 5RK90GU-CF | 5RK90GU-CFT | 90 | 1ph220 | 50 | 0.82 | 560 | 700 | 1250 | 6 |

| (5RK90A-CF) | (5RK90A-CFT) | 90 | 1ph230 | 50 | 0.81 | 560 | 700 | 1250 | 6 |

| 5RK90GU-HF | 5RK90GU-HFT | 90 | 1ph220 | 60 | 0.81 | 560 | 570 | 1550 | 6 |

| (5RK90A-HF) | (5RK90A-HFT) | 90 | 1ph230 | 50 | 0.8 | 560 | 570 | 1550 | 6 |

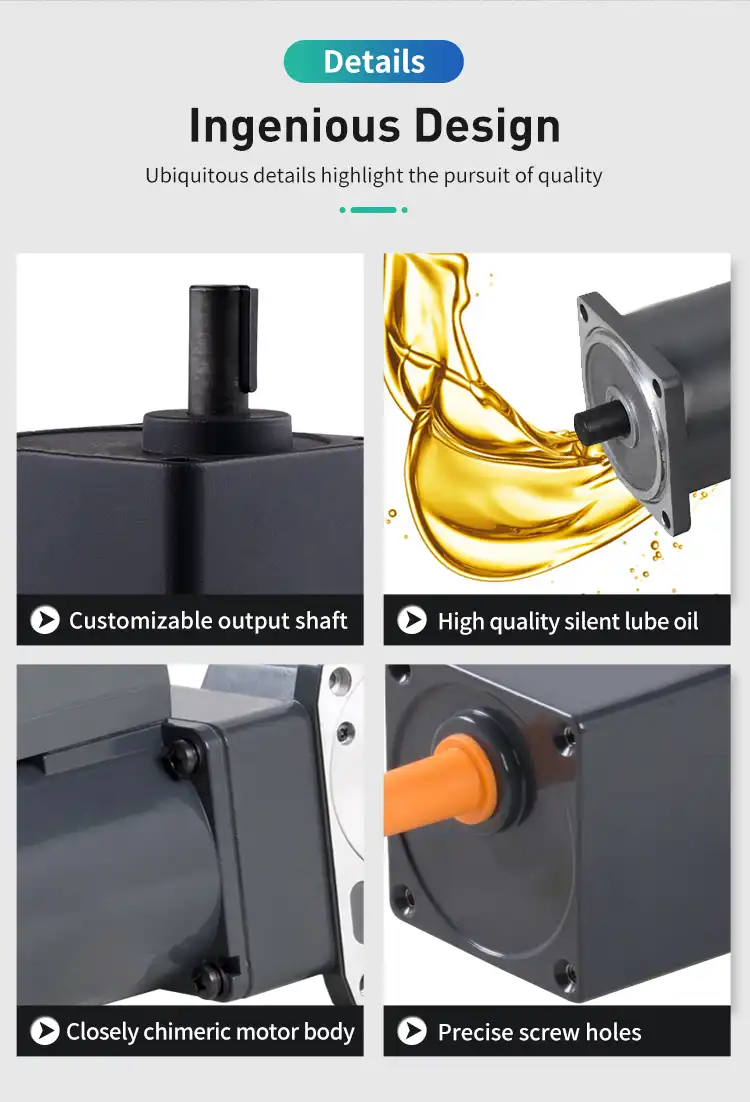

Product Display

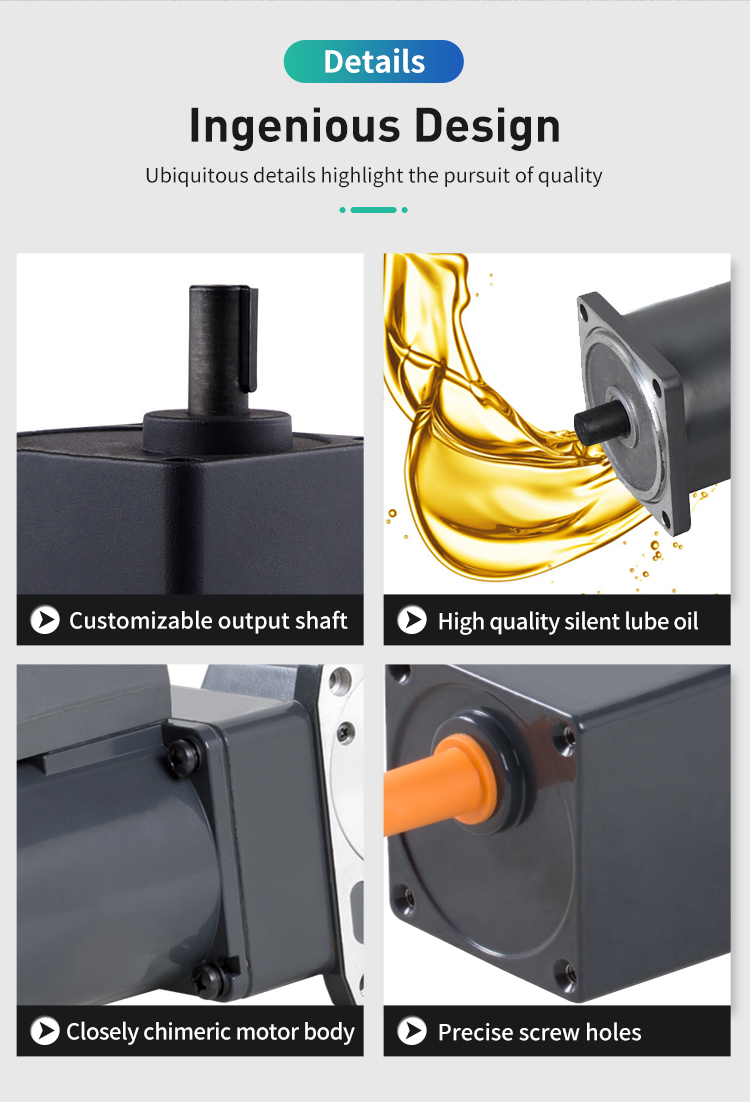

Product Feature

High Torque Output

This 90W 1phase AC Gear Motor with Terminal Box delivers a robust torque of 16Nm, offering substantial power for heavy-duty applications. Designed to maintain reliable performance even under strenuous conditions, it's perfect for demanding tasks requiring high torque output.

Variable Speed

Featuring a speed range capsulating 0-135RPM, this motor allows for precise operational control. With the flexibility to dynamically adjust the motor speed according to the desired application, it offers optimal performance and adaptability across a variety of operational scenarios.

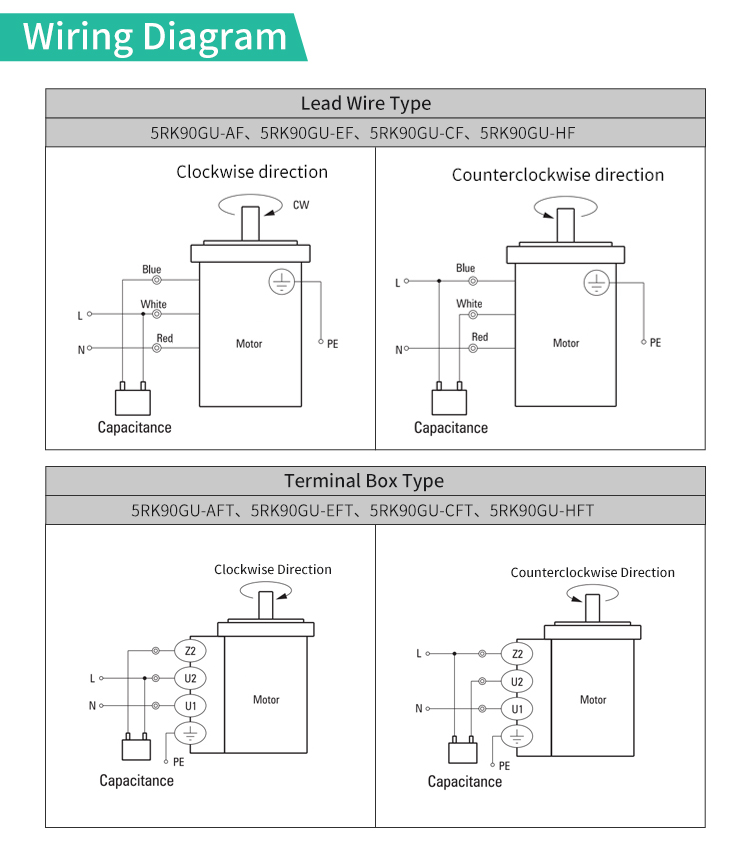

Bidirectional Operation

Built as a reversible gear motor, our 90W AC motor can seamlessly change rotational direction. This makes it an excellent fit for apparatuses like conveyor systems and hoists that necessitate rotational direction shifts, providing flexibility and versatility.

Energy-Efficient Design

Our 90W 1phase AC Gear Motor is optimized for energy efficiency, curbing operational expenses over time. This allows it to be the ideal choice for continuous use in industrial environments where energy conservation matters, supporting resourceful use and backing sustainability goals.

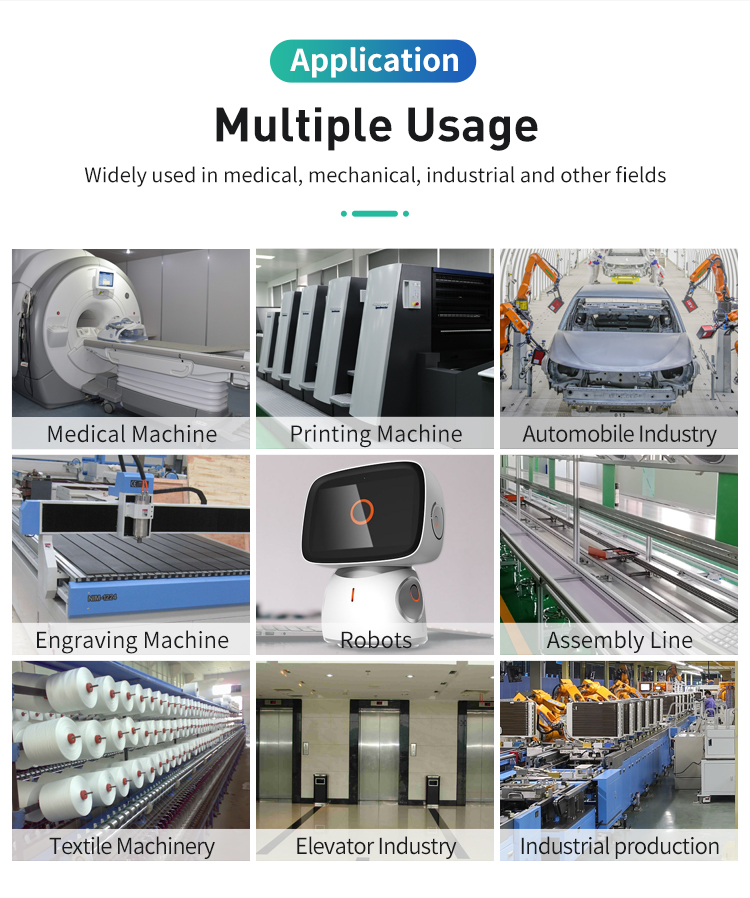

Product Applications

Trustworthy for Industrial Machinery

Well-suited for heavy machinery, our 90W AC gear motor presents consistent power and adaptability to fluctuating loads. Robust enough to endure intense industrial conditions, it backs trustworthy performance in applications like conveyor systems and industrial mixers.

Perfect for Robotics

The 90W AC gear motor's variability and precision in speed make it excellent for robotic applications. It offers fine control and reliability, enabling accurate movement and positioning in industrial automation, collaborative robots (cobots), and other robotic systems.

Useful in Automotive Applications

Autonomous industry finds our 90W AC gear motor especially valuable in equipment requiring torque and reversal functionality. Its versatility improves assembly lines, maintenance platforms, and more, ensuring smooth and adaptable operation.

Efficient in Agricultural Equipment

Our AC Gear Motor integrates flawlessly into agricultural machinery, fitting into high torque demand perfectly. From powering conveyors, grain augers, farm harvesters to feed mixers, this motor lends unmatched strength and reliability to agricultural rigs.

Suitable for Home Appliance Manufacturing

Given its adaptability and efficiency, home appliance manufacturers highly appreciate our motor. From appliances demanding silent operation, durability, to precision control, this motor truly stands out.

Related Products

Videos

DIMENSIONS

Technical Documents Downloads

| File Name | Size | Download |

| AC-Motor-Catalog.pdf | 23.4MB | Download |

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00