400W 220-380V High Torque Horizontal Vertical AC Gear Reduction Brake Motor

$93.00

This 400W 220-380V high torque AC gear reduction brake motor is an excellent choice for demanding applications, delivering efficient power with a maximum torque of over 300Nm. Its versatile design is suitable for both horizontal and vertical use, allowing for fantastic flexibility.

SPECIFICATIONS

|

Power |

100W~7500W |

|

Voltage |

1-phase 110V/ 220V |

|

3-phase 220V/ 380V |

|

|

Output Shaft Dia (mm) |

18 / 22/ 28/ 32/ 40/ 50 /60 |

|

Ratio |

3、5、10、........1800 |

|

Brake |

Hand release / DC24V brake |

|

Environment |

Temperature: -10℃~+40℃ Humidity: ≤90% |

|

Installation |

Horizontal/ Vertical |

|

Material |

Aluminum |

|

Usage |

Air conditioner, washing machine, vacuum cleaner, automatic gate, power tool, medical appliance |

Product Display

Product Feature

Outstanding Torque Ouput

The Lunyee 400W AC Gear Reduction Brake Motor provides an exceptional torque of 16Nm. Engineered for demanding tasks that require high torque, this motor ensures powerful, reliable performance under intense conditions, making it the unequivocal choice for heavy-duty needs.

Fine-Tuned Variable Speed

Our motor offers a wide speed range of 0-135RPM, providing you with precise control over your operations. This flexibility, combined with the ability to adjust the motor speed to match the requirements of the application, ensures optimal performance across a variety of scenarios.

Effortless Bidirectional Operation

Designed as a reversible gear motor, our 400W AC motor can fluidly change rotational directions. This makes it an excellent fit for equipment like conveyor systems and hoists that require shifts in rotational direction, offering both convenience and versatility.

Energy-Efficient Design

Maximizing energy efficiency, our 400W AC Gear Reduction Brake Motor reduces operational costs over time. It's the perfect choice for continual use in industrial environments where sustainability and resource optimization are priorities, reducing energy consumption effectively.

Product Applications

Reliable Performance for Industrial Machinery

Withstand the rigors of heavy machinery with our AC brake motor. Displaying consistent power and adaptability to varying loads, it meets demanding industrial standards, ensuring reliable performance across various heavy-duty applications.

Excellence in Robotics

Given the motor's precision and speed variability, it stands as a superb choice for robotics. It offers dependable fine control, making it suitable for industrial automation, collaborative robots (cobots), and other robotic systems that need precision movement and positioning.

Automotive Applications

Our AC brake motor carves a niche in the automotive industry, particularly useful in tasks that require torque and reversal functionality. Its versatility enhances assembly lines, maintenance platforms, and more.

Efficacy in Agricultural Equipment

Our AC Gear Reduction Brake Motor integrates seamlessly with agricultural machinery, particularly those requiring high torque. Lend power to conveyors, grain augers, harvesters, and more with this motor's unmatched strength and reliability.

Modern Home Appliance Manufacturing

Known for its adaptability and efficiency, our motor is highly favored by home appliance manufacturers. It's perfect for appliances requiring silent operation, longevity, and precision control.

Related Products

Videos

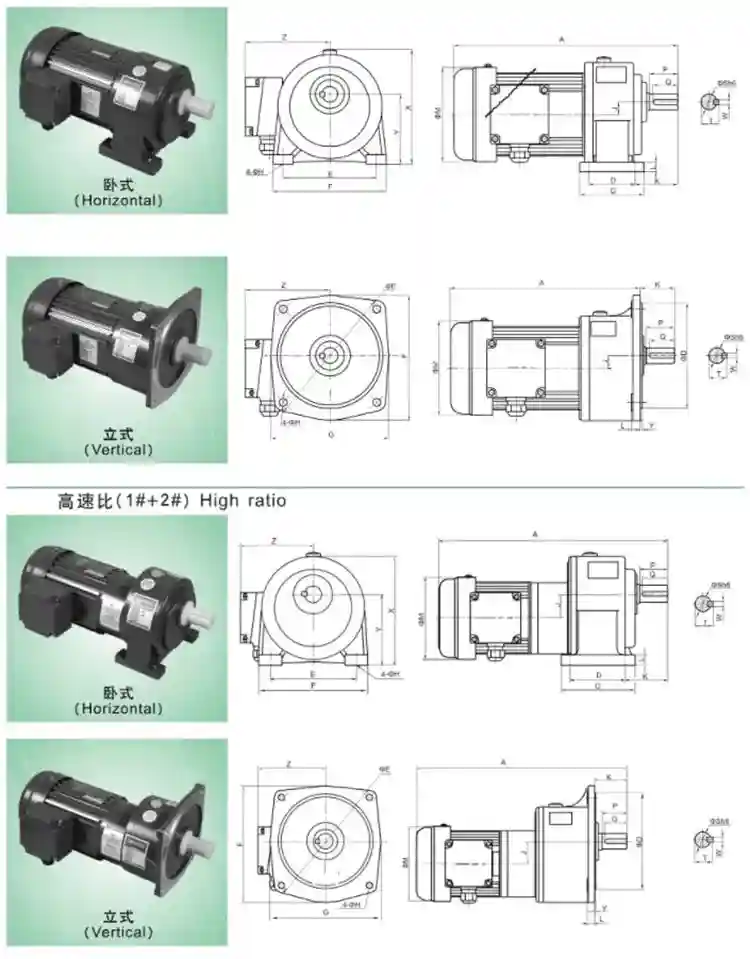

DIMENSIONS

Technical Documents Downloads

| File Name | Size | Download |

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00