SPECIFICATIONS

| Voltage | Power | Driver Model | Flange (mm) |

Motor Model |

Rated Speed |

Rated torque |

| 380V | 1KW | EPS-B1-0001BA-A000 | 130 | 130DNMB1-0001AKAM | 1000rpm | 9.55N.m |

| 380V | 1KW | EPS-B1-0001BA-A000 | 130 | 130DNMB1-0001BKAM | 1500rpm | 6.37N.m |

| 380V | 1KW | EPS-B1-0001BA-A000-G | 130 | 130DNMB2-0001CKAM | 2000rpm | 4.77N.m |

| 380V | 1KW | EPS-B1-0001BA-A000-G | 130 | 130DNMB1-0001DKAM | 3000rpm | 3.18N.m |

| 380V | 1.2KW | EPS-BI-01D2BA-A000 | 130 | 130DNMB1-01D2CKAM | 2000rpm | 5.73N.m |

| 380V | 1.5KW | EPS-BI-01D5BA-A000 | 130 | 130DNMB1-01D5AKAM | 1000rpm | 14.33N.m |

| 380V | 1.5KW | EPS-BI-01D5BA-A000 | 130 | 130DNMB1-01D5BKAM | 1500rpm | 9.55N.m |

| 380V | 1.5KW | EPS-BI-01D5BA-A000 | 130 | 130DNMB2-01D5CKAM | 2000rpm | 7.16N.m |

| 380V | 1.5KW | EPS-BI-01D5BA-A000 | 130 | 130DNMB1-01D5DKAM | 3000rpm | 4.77N.m |

| 380V | 2KW | EPS-B1-02D2BA-A000 | 130 | 130DNMB2-0002BKAM | 1500rpm | 12.73N.m |

| 380V | 2.2KW | EPS-B1-02D2BA-A000 | 130 | 130DNMB2-0002CKAM-Z02 | 2000rpm | 9.55N.m |

| 380V | 3KW | EPS-BI-0003BA-A000 | 130 | 130DNMB2-0003CKAM | 2000rpm | 14.33N.m |

| 380V | 3KW | EPS-BI-0003BA-A000 | 130 | 130DNMB1-0003DKAM | 3000rpm | 9.55N.m |

| 380V | 3KW | EPS-BI-0003BA-A000 | 180 | DNBB18-0003AK1AMS | 1000rpm | 28.6N.m |

| 380V | 3KW | EPS-BI-0003BA-A000 | 180 | DNBB18-0003BK1AMS | 1500rpm | 19.1N.m |

| 380V | 3KW | EPS-BI-0003BA-A000 | 180 | DNBB18-0003CK1AMS | 2000rpm | 14.33N.m |

| 380V | 3.7KW | EPS-B1-04D5BA-A000 | 180 | DNBB18-03D7AK1AMS | 1000rpm | 35N.m |

| 380V | 4KW | EPS-B1-04D5BA-A000 | 130 | 1300MB1-04D5DKAM | 3000rpm | 12.73N.m |

| 380V | 4KW | EPS-B1-04D5BA-A000 | 180 | DNBB18-0004BK1AMS | 1500rpm | 25.5N.m |

| 380V | 4KW | EPS-B1-04D5BA-A000 | 180 | DNBB18-0004CK1AMS | 2000rpm | 19.1N.m |

| 380V | 4.5KW | EPS-B1-04D5BA-A000 | 130 | I300MB1-04D5DKAM | 3000rpm | 14.33N.m |

| 380V | 4.5KW | EPS-B1-04D5BA-A000 | 180 | DNBB18-04D5BK1AMS | 1500rpm | 28.6N.m |

| 380V | 4.5KW | EPS-B1-04D5BA-A000 | 180 | DNBB18-04D5CK1AMS | 2000rpm | 21.5N.m |

| 380V | 5KW | EPS-B1-05D5BA-A000 | 180 | DNBB18-0005CK1AMS | 2000rpm | 23.8N.m |

| 380V | 5.5KW | EPS-B1-05D5BA-A000 | 180 | DNBB18-05D5BK1AMS | 1500rpm | 35N.m |

| 380V | 7.5KW | EPS-B1-07D5BA-A000 | 180 | DNBB18-07D5BK1AMS | 1500rpm | 47.7N.m |

| 380V | 7.5KW | EPS-B1-07D5BA-A000 | 220 | DNBB22-07D5BK1AMS | 1500rpm | 47.8N.m |

| 380V | 8.5KW | EPS-B1-08D5BA-A000 | 200 | 200DMB1-08D5CEAM | 1500rpm | 54.1N.m |

| 380V | 11KW | EPS-B1-0011BA-A000 | 200 | 200MMB1-0011BEAM | 1500rpm | 70N.m |

| 380V | 11KW | EPS-B1-0011BA-A000 | 200 | 20DMB1-0011CEAM | 2000rpm | 52.5N.m |

| 380V | 15KW | EPS-B1-0015BA-A000 | 200 | 2000MB1-0015BEAM | 1500rpm | 95.5N.m |

| 380V | 22KW | EPS-B1-0022BA-A000 | 200 | 200DMB1-0022BEAM | 1500rpm | 140N.m |

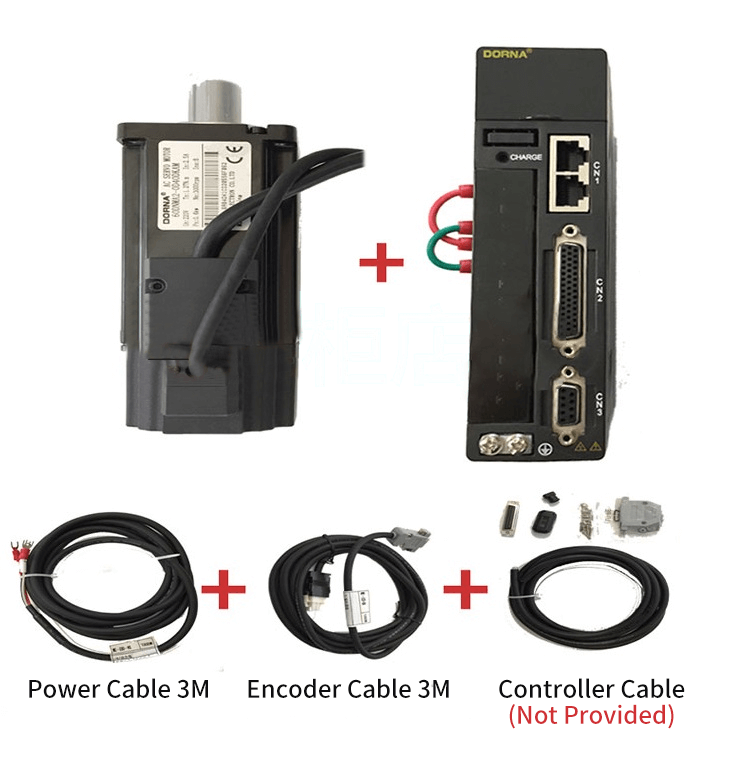

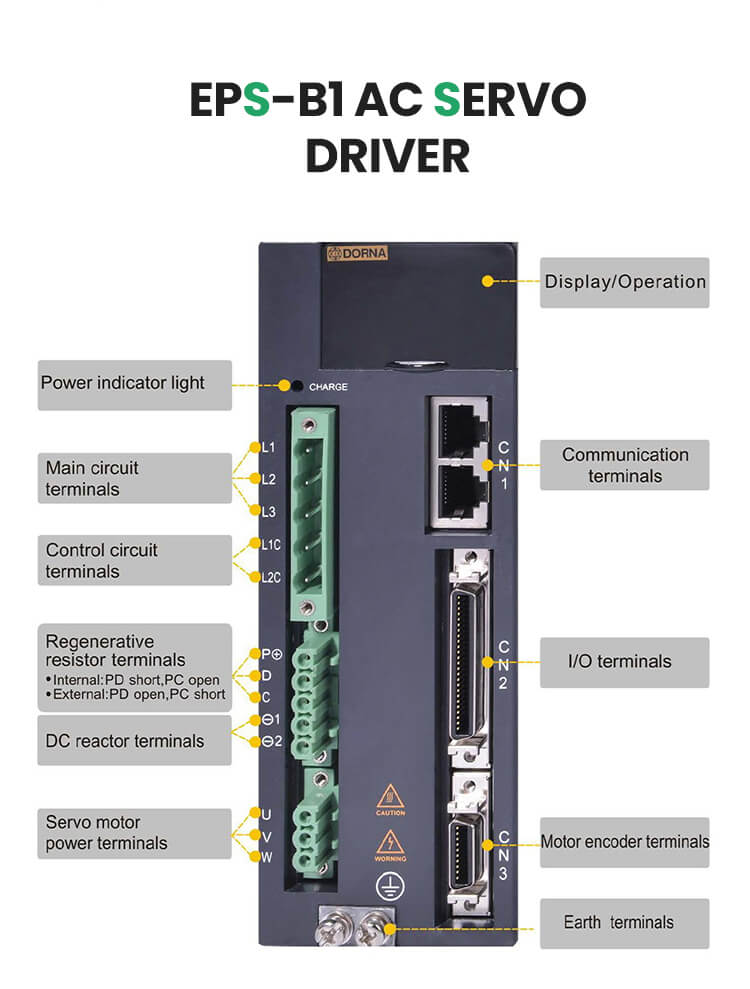

Product Display

How to choose suitable servo motor?

- 1. Confirm torque/speed/power ( Providing any two parameters is ok)

- 2. Choose the motor flange size (Commonly is 40mm, 60mm, 80mm, 90mm, 110mm, 130mm, 150mm, 180mm, 200mm)

- 3. Confirm servo motor accuracy: incremental encoders (2500 lines/5000 lines) Or absolute encoders (17-bit/20-bit/23-bit).

- 4. Select suitable motor driver.

Product Feature

High-Precision Performance

Integrated hybrid servo drive system with communication function

Prevents out-of-step issues for reliable operation

Powerful Torque Delivery

High-speed torque attenuation significantly lower than open-loop drives

Improves high-speed performance and torque output of stepper motors

Ensures robust torque for demanding applications

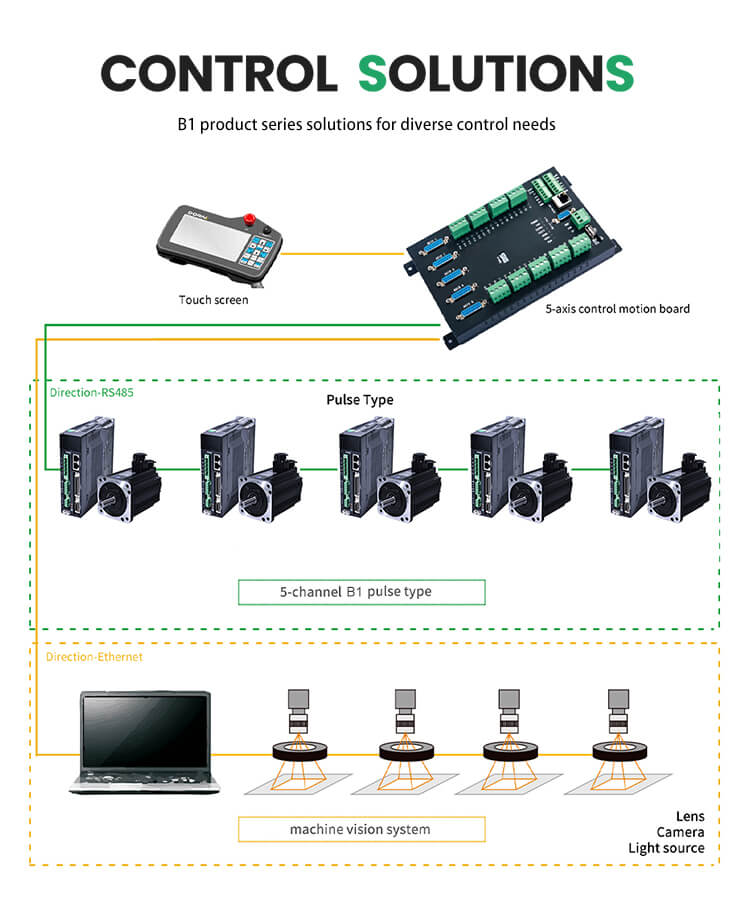

Integrated Communication

Enables precise position and speed control via communication

Facilitates seamless integration with control systems

Rugged and Durable Design

Constructed with high-hardness metal for superior durability

Sturdy construction withstands demanding industrial environments

Matte textured sidewall increases friction for enhanced grip

Versatile and Adaptable

Suitable for a wide range of industrial machinery and applications

Elevates precision and performance of existing equipment

Customizable solutions available for specific requirements

Product Applications

Industrial Automation

Servo motors are widely used in industrial automation systems, such as pick-and-place machines, packaging equipment, assembly lines, and robotic arms, providing precise positioning and motion control.

Computer Numerical Control (CNC) Machines

CNC machines, including milling machines, lathes, and routers, rely on servo motors for accurate and repeatable positioning of cutting tools and workpieces during manufacturing processes.

Semiconductor and Electronics Manufacturing

The production of semiconductors, printed circuit boards, and electronic components requires servo motors for precise positioning and motion control during processes like die bonding, wire bonding, and component placement.

Robotics and Automation

Servo motors are used in various robotic applications, including industrial robots, collaborative robots (cobots), and service robots, enabling precise and coordinated movements for tasks like assembly, welding, and material handling.

Printing and Packaging Machinery

The packaging and printing industries utilize servo motors in machines like labelers, form-fill-seal machines, and high-speed printing presses for precise web handling, registration, and motion control.

Machine Tools and Woodworking

Servo motors are used in machine tools like lathes, milling machines, and woodworking equipment, providing accurate positioning and motion control for cutting, shaping, and drilling operations.

Renewable Energy Systems

Servo motors play a role in renewable energy systems, such as wind turbines and solar tracking systems, enabling precise positioning and control of turbine blades and solar panels for optimal energy capture.

Related Products

Videos

DIMENSIONS

Technical Documents Downloads

| File Name | Size | Download |

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00