Holding Torque on DC Motor

2024-07-09 16:52:04

Understanding holding torque in the context of DC motors is critical for everyone working in various fields of automation, robotics, and precision motion control. Holding torque refers to the torque necessary to keep a motor shaft stationary when the motor is powered and is a crucial factor in applications where maintaining a specific position is essential. In this article, we'll explore the concept of holding torque, its significance, how it compares to detent torque, and its impacts on motor performance, providing a technical yet accessible guide.

Introduction to Holding Torque

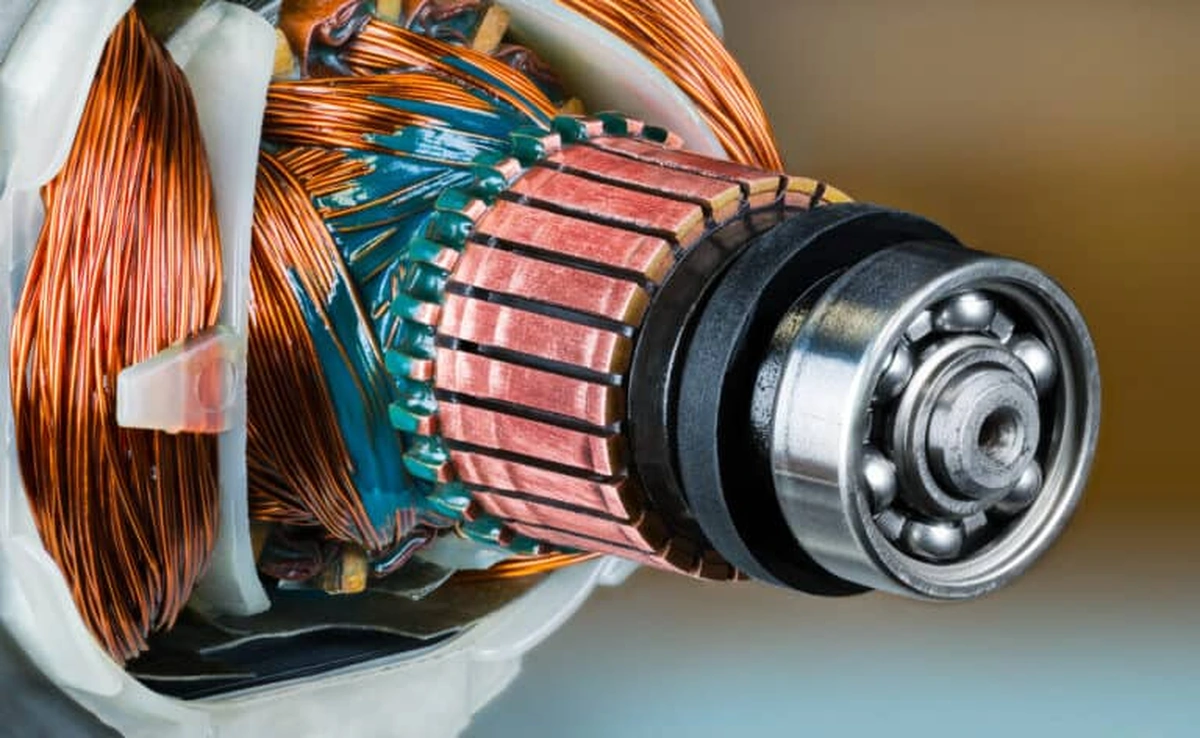

DC motors are well-known for their ability to convert electrical energy into mechanical rotation. However, an often overlooked aspect is their ability to resist movement when energized. The holding torque is that resistance against external forces, ensuring the motor maintains its position when halted.

Understanding Holding Torque in DC Motors

Specifically, holding torque can be defined as the amount of torque required to move a motor's rotor from a fixed position with energized windings but without actual rotation. It represents the motor's capability to hold a load at a standstill and is directly influenced by the current flowing through the motor's windings.

Significance of Holding Torque

The significance of holding torque cannot be understated in precision applications. It's particularly relevant in machine designs where a DC motor must maintain a load immobile against an external force without physical supports or breaks. Holding torque plays a crucial role in various applications where position holding, stability, and resistance to external forces are required. For example, this aspect is vital in direct-drive turntables, camera stabilizers, and robotics, where positional integrity is paramount. Some key areas where holding torque is of utmost significance include:

- Robotics and Automation: In robotic systems, holding torque is vital for maintaining the position of robotic arms, grippers, and other components. It ensures stability during pick-and-place operations, assembly tasks, and precise motions. Holding torque allows robots to maintain their position even when external forces act upon them, ensuring accurate and repeatable operations.

- CNC Machining: In computer numerical control (CNC) machines, holding torque is critical for keeping the spindle in position during machining operations. It prevents unwanted movement or deflection, ensuring precise cutting, drilling, and milling. Holding torque also contributes to the overall stiffness of the machine, enhancing its stability and accuracy.

- Medical and Scientific Instruments: In medical equipment and scientific instruments, holding torque is essential for maintaining the position of delicate components during procedures or measurements. It ensures stable positioning of surgical tools, imaging devices, and analytical instruments, enhancing precision and reducing the risk of errors.

- Robotics and Prosthetics: Holding torque is of significant importance in robotic prosthetics, allowing users to maintain a stable position during various activities. It enables precise control over movements and ensures a secure grip, enhancing the functionality and usability of prosthetic devices.

Calculating and Maximizing Holding Torque

The holding torque of a DC motor can be calculated using the following formula:

Holding Torque (Nm) = Kt × I

Where:

- Kt is the motor's torque constant (Nm/A).

- I is the current applied to the motor windings (A).

To maximize holding torque, several factors should be considered:

- Optimal Current Selection: Applying an appropriate amount of current to the motor windings is crucial for achieving maximum holding torque. Operating the motor below or above its rated current can result in reduced holding torque and potential overheating or damage. Proper current selection ensures optimal performance and stability.

- Motor Design and Construction: The design and construction of the motor significantly impact its holding torque capabilities. Factors such as the number of stator poles, rotor design, and winding configurations influence the motor's torque output. Selecting motors specifically designed for high holding torque applications can ensure optimal performance.

- Motor Driver Selection: The motor driver, which controls the current flowing through the motor windings, plays a vital role in maximizing holding torque. Choosing a motor driver with appropriate current control capabilities and protection features ensures efficient current management and enhances the motor's holding torque performance.

Conclusion

Unlike detent torque, holding torque provides stability and resistance to external forces in various applications ranging from robotics and automation to CNC machining, medical instruments, and prosthetics. By understanding the concept of holding torque, calculating it accurately, and maximizing it through optimal current selection, motor design, and motor driver selection, you can ensure precise and stable positioning in their motion control systems. As technology advances, advancements in motor design and control techniques will continue to enhance the holding torque capabilities of DC motors, expanding their applications and providing greater control and stability in a wide range of industries.

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00