Gearbox Selection Guide

2024-06-17 16:52:46

The gearbox is an essential component in machinery and vehicles, significantly impacting their performance, efficiency, and reliability. This guide aims to provide a comprehensive approach to selecting the right gearbox for your application, ensuring optimal compatibility and performance.

Understanding Gearbox Basics

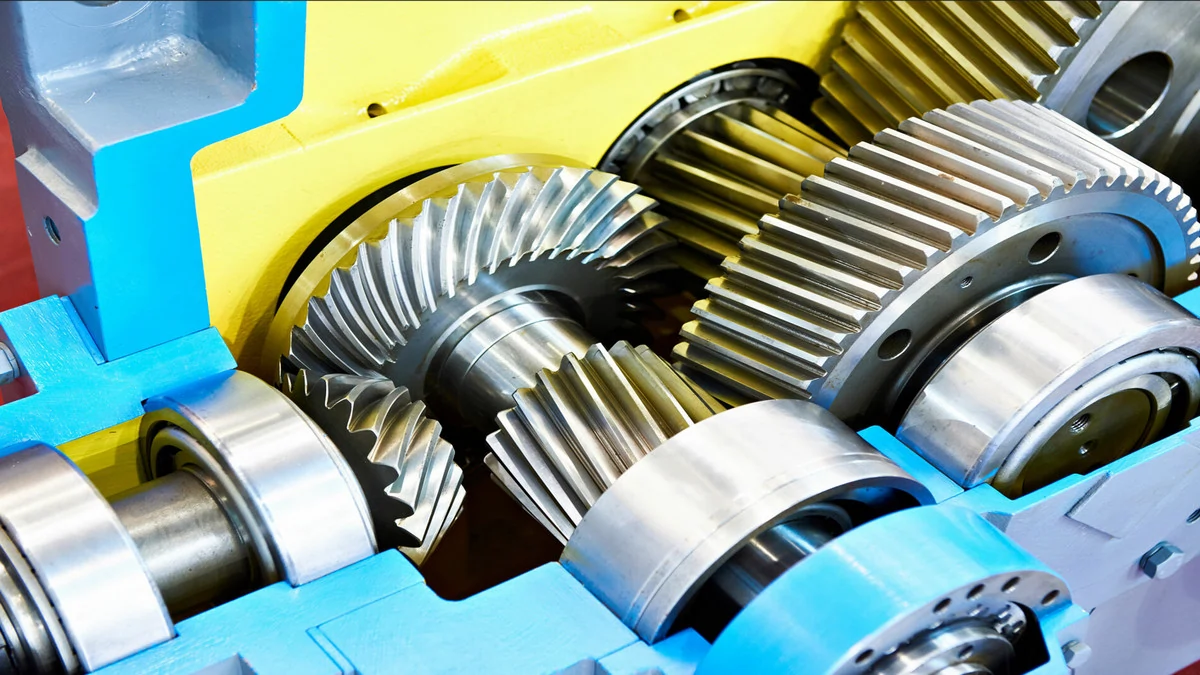

A gearbox, also known as a gear reducer, is a mechanical device that contains a set of gears designed to transmit power and change the rotational characteristics of a system. It involves the meshing of gears with different sizes and configurations to achieve the desired output.

Types of Gearboxes

There are various types of gearboxes, including spur gear, helical gear, bevel gear, worm gear, planetary gear, and more. Each type has distinct advantages and is suitable for specific applications based on factors such as torque requirements, speed ratios, efficiency, noise level, and space constraints. Different gearboxes have different characteristics and therefore are suitable for different applications.

Helical Gearboxes

Advantages: Offer smooth and quiet operation with a high degree of efficiency.

Applications: Widely used in various industrial applications including conveyors, mixers, and extruders.

Bevel Gearboxes

Advantages: Capable of changing the rotation angle, suitable for high-speed applications.

Applications: Ideal for applications requiring turning corners like automobiles and differential systems.

Worm Gearboxes

Advantages: Provide high-ratio speed reduction in a small space with a locking feature when not in motion.

Applications: Used in material handling systems, conveyors, and elevators.

Factors to Consider in Gearbox Selection

Load Requirements

Understanding the load characteristics of your application is crucial in selecting an appropriate gearbox. Consider factors such as torque, speed, and duty cycle to ensure the gearbox can handle the anticipated loads without compromising performance or reliability.

Speed Ratios and Output Speed:

Evaluate the required speed ratios and the desired output speed for your application. Different gear configurations offer varying speed reduction capabilities, allowing you to match the motor speed to the driven load effectively.

Efficiency

Efficiency is an essential consideration, as it influences the power transmission capability and energy consumption of the gearbox. Higher efficiency gearboxes result in reduced power losses and improved overall system efficiency.

Space Constraints

Evaluate the available space for the gearbox installation. Consider the dimensions, mounting options, and overall footprint of the gearbox to ensure compatibility with your application's physical constraints.

Environmental Considerations

Assess the environmental conditions in which the gearbox will operate. Factors such as temperature, humidity, dust, and corrosive substances can impact the gearbox's performance and lifespan. Choose a gearbox that is designed to withstand the specific environmental challenges of your application.

Noise and Vibration

In applications where noise and vibration are a concern, select gearboxes designed to minimize these effects. Helical and planetary gearboxes, for example, are known for their smoother operation and reduced noise compared to spur gearboxes.

Maintenance and Serviceability

Consider the maintenance requirements and ease of serviceability of the gearbox. Access to lubrication points, ease of gear replacement, and availability of spare parts can impact the overall cost of ownership and downtime in case of maintenance or repairs.

Application-Specific Considerations

Industrial Machinery

Gearboxes are widely used in industrial machinery, such as conveyors, mixers, agitators, and cranes. In these applications, factors such as torque requirements, speed control, and reliability play a crucial role in selecting the appropriate gearbox.

Automotive and Transportation

Automotive applications, including vehicles, trucks, and motorcycles, require gearboxes for transmitting power from the engine to the wheels. Factors such as torque capacity, gear shifting smoothness, and durability are vital considerations in this domain.

Robotics and Automation

Gearboxes in robotic systems and automation equipment must provide precise motion control, high torque capacity, and compact designs. Efficiency, backlash, and theability to handle dynamic loads are critical factors in selecting gearboxes for robotics.

Renewable Energy

Gearboxes are integral components in wind turbines and solar tracking systems, where they convert low-speed, high-torque rotation into high-speed rotation for power generation. Factors such as efficiency, reliability, and resistance to extreme weather conditions are crucial in these applications.

Conclusion

Selecting the right gearbox is a crucial step in ensuring optimal performance, reliability, and efficiency in mechanical applications. By considering factors such as load requirements, speed ratios, efficiency, space constraints, and environmental conditions, you can choose the right gearbox.

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00