DC Motor Inrush Current

2024-08-13 14:13:55

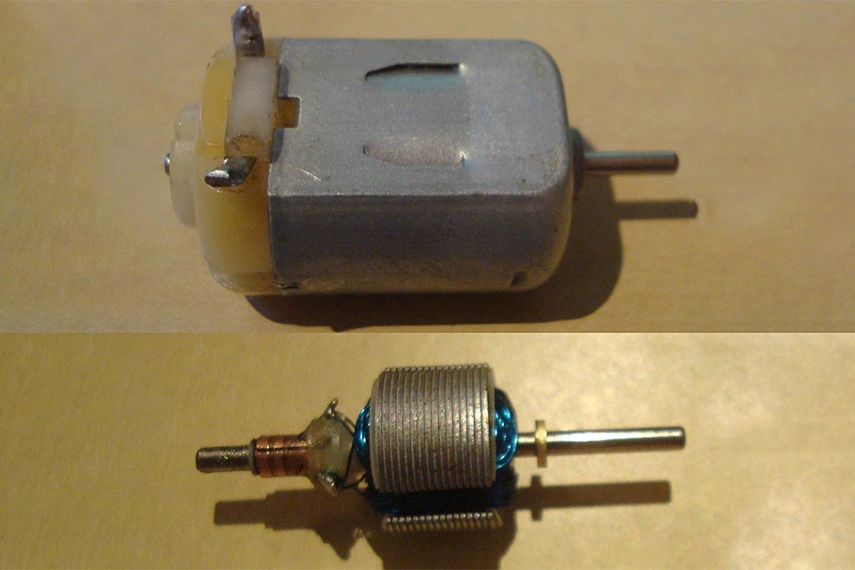

Inrush current is a significant aspect of electrical systems, particularly in DC motors. Understanding and managing inrush current is crucial for ensuring the safe and efficient operation of DC motors, which are widely used in various industrial, commercial, and consumer applications. This article delves into the concept of inrush current in DC motors, its causes, effects, and methods for mitigation.

Understanding Inrush Current

Definition and Characteristics

Inrush current, also known as surge current, is the initial surge of current that flows into an electrical device when it is first turned on. For DC motors, this surge can be several times higher than the motor's rated current. This occurs because the motor's inductance initially presents little opposition to the flow of current, allowing a large current to flow until the magnetic field builds up.

Causes of Inrush Current in DC Motors

- Initial Magnetization: When a DC motor starts, the inductance of the windings initially offers low resistance to current flow. This results in a high inrush current until the magnetic field stabilizes.

- Mechanical Load: The initial mechanical load on the motor can also cause high inrush current. If the motor starts under load, it requires more torque, leading to a higher current draw.

- Capacitive Components: Capacitive elements within the motor circuit can contribute to inrush current. The capacitors draw a large amount of current initially to charge up to the supply voltage.

Effects of Inrush Current

- Electrical Stress: Inrush current can cause significant stress on electrical components, including wires, contacts, and circuit breakers. This can lead to overheating and potential damage.

- Voltage Drops: The sudden surge of current can cause voltage drops in the power supply network, potentially affecting other connected devices and systems.

- Nuisance Tripping: Circuit breakers and protection devices may trip unnecessarily due to the high initial current, leading to operational disruptions.

- Reduced Lifespan: Repeated exposure to inrush current can reduce the lifespan of the motor and associated components due to thermal and mechanical stress.

Measuring Inrush Current

Accurately measuring inrush current is essential for designing appropriate protection and mitigation strategies. Several methods can be used:

- Clamp Meters: Specialized clamp meters designed for inrush current measurement can capture the peak current during motor startup.

- Oscilloscopes: Oscilloscopes with current probes can provide detailed waveforms of the inrush current, helping to analyze its characteristics.

- Data Loggers: Data loggers can record inrush current over time, providing valuable insights into the motor's startup behavior.

Mitigation Techniques for Inrush Current

Soft Starters

Soft starters are devices that gradually increase the voltage supplied to the motor, reducing the inrush current. They work by controlling the phase angle of the voltage, ensuring a smooth and gradual increase in current. This not only reduces inrush current but also minimizes mechanical stress on the motor.

Inrush Current Limiters

Inrush current limiters, such as thermistors, are placed in series with the motor. These components have a high initial resistance that limits the inrush current. As the motor continues to run, the thermistor heats up and its resistance decreases, allowing normal current flow.

Pre-Charging Circuits

Pre-charging circuits are used to charge capacitive components gradually before the full voltage is applied to the motor. This helps to limit the initial surge of current.

Controlled Switching

Using controlled switching techniques, such as zero-crossing switching, can help reduce inrush current. By switching the motor on at the point where the AC supply voltage crosses zero, the initial current surge can be minimized.

Designing for Inrush Current

Selection of Components

When designing systems involving DC motors, it is crucial to select components that can handle the expected inrush current. This includes choosing appropriately rated fuses, circuit breakers, and wiring.

Circuit Protection

Incorporating circuit protection devices specifically designed to handle inrush current is essential. This includes time-delay fuses and circuit breakers with higher inrush current ratings.

Motor Control Systems

Advanced motor control systems can help manage inrush current. Variable frequency drives (VFDs) and motor controllers with inrush current limiting features can provide precise control over the motor startup process.

Applications and Case Studies

Industrial Applications

In industrial settings, managing inrush current is critical to maintaining operational efficiency and safety. For example, large conveyor systems and pumps that use DC motors can benefit from soft starters and inrush current limiters to prevent system disruptions and equipment damage.

Commercial Applications

In commercial applications, such as HVAC systems and elevators, reducing inrush current can enhance system reliability and prevent unnecessary downtime. Implementing soft starters and controlled switching can significantly improve performance.

Consumer Applications

In consumer electronics and appliances, managing inrush current can enhance product lifespan and reliability. Devices like washing machines and power tools often use DC motors that benefit from inrush current mitigation techniques.

Conclusion

Inrush current is a critical factor in the operation of DC motors, impacting both the performance and longevity of the motor and associated components. Managing inrush current not only protects electrical systems from potential damage but also enhances overall system reliability and performance. By employing techniques such as soft starters, inrush current limiters, and controlled switching, you can ensure the safe and efficient operation of DC motors across various applications.

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00