2-Phase vs. 5-Phase Stepper Motors

2024-07-16 09:13:12

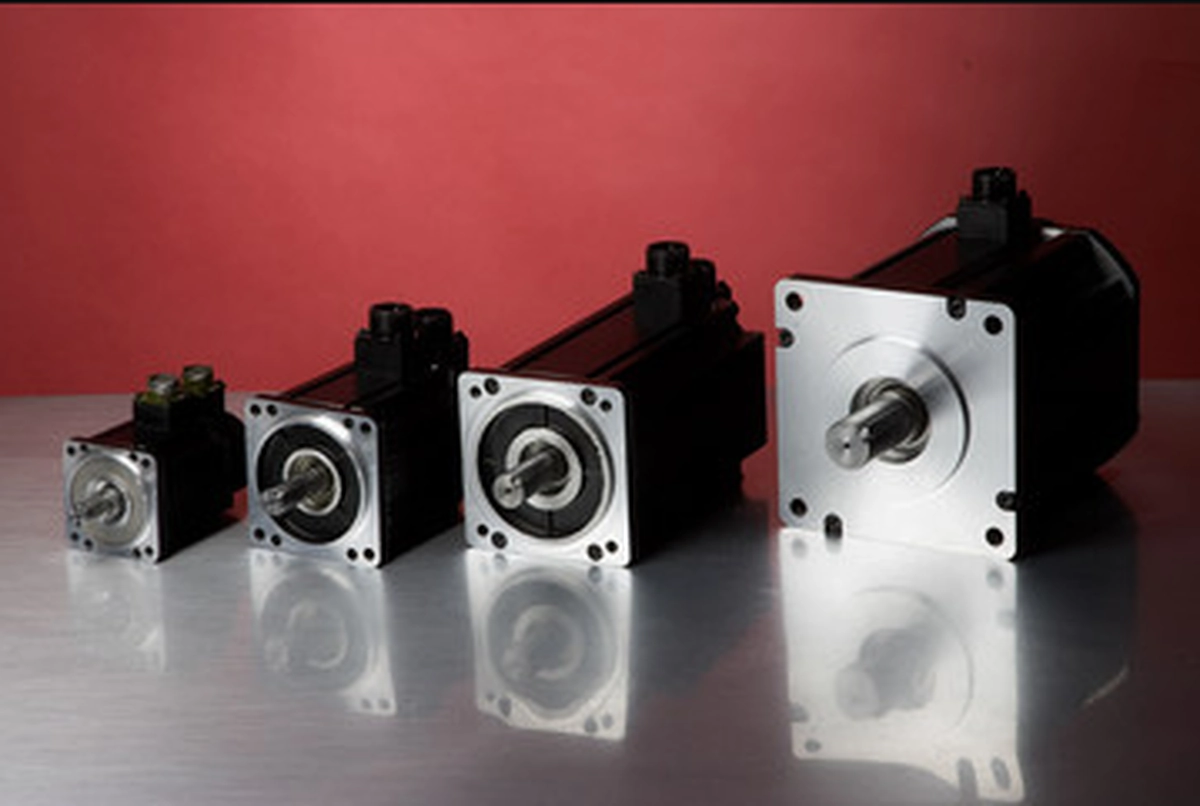

Stepper motors are widely used in various industries for their precise positioning capabilities and ease of control. Two common types of stepper motors are the 2-phase and 5-phase motors. While both types serve similar purposes, they differ in their construction and performance characteristics. This article explores the differences between 2-phase and 5-phase stepper motors, providing an in-depth analysis of their technology, advantages, and applications.

Understanding 2-Phase Stepper Motors

2-phase stepper motors, also known as bipolar stepper motors, are the most commonly used type of stepper motor. They typically have two windings, each connected to a separate phase. The motor's rotor steps in response to changes in the current direction flowing through the windings. The step angle of a 2-phase stepper motor is typically 1.8 degrees, resulting in 200 steps per revolution.

Understanding 5-Phase Stepper Motors

5-phase stepper motors, also known as unipolar stepper motors, have five or more windings, each connected to a separate phase. These motors offer finer step resolutions compared to 2-phase motors, typically ranging from 0.72 to 0.36 degrees per step. The multiple windings allow for more precise control and smoother motion.

Fundamental Differences

Mechanical Structure

The primary distinction between 2-phase and 5-phase stepper motors lies in their mechanical setup, specifically the stator and rotor configurations. In a 2-phase stepper motor, the stator is comprised of 8 magnetic poles, each equipped with small teeth. Conversely, the 5-phase stepper motor stator includes 10 magnetic poles. This variation directly influences the sequence and nature of electromagnetic interactions within these motors.

Number of Phases

As the names suggest, 2-phase motors operate with two phases, known as "A" and "B" phases, while 5-phase motors have five separate phases. The number of phases dictates the possible combinations of poles energized in sequence, which farther affects the motor's performance across various metrics.

Performance Comparison

Resolution

The resolution of a stepper motor measures the fineness of the control it offers over movement. Due to the greater number of poles (10 poles, 2 per phase), 5-phase motors can achieve a higher resolution, with 500 steps per rotation (0.72° per step), compared to 200 steps per rotation (1.8° per step) in 2-phase motors. This higher resolution enhances control precision significantly.

Vibration

Vibration levels are a critical factor in precision applications. 5-phase stepper motors offer a notable reduction in vibration compared to 2-phase motors. This difference is attributed primarily to the smaller step angles (0.72° for 5-phase versus 1.8° for 2-phase), which facilitate smoother transitions and less mechanical stress.

Differences in Performance

- Precision and Resolution: One significant advantage of 5-phase stepper motors is their higher step resolution. The additional windings enable finer control, resulting in smoother and more precise positioning. This makes 5-phase motors suitable for applications that require high accuracy and smooth operation, such as robotics, medical equipment, and semiconductor manufacturing.

- Torque and Speed: 2-phase stepper motors typically offer higher torque at lower speeds compared to 5-phase motors. However, 5-phase motors can achieve higher speeds while maintaining excellent torque characteristics. This makes them suitable for applications that require rapid movements and acceleration, such as high-speed pick-and-place machines and printing systems.

- Power Consumption: Due to their multiple windings, 5-phase stepper motors generally consume more power than 2-phase motors. However, advancements in motor design and control technologies have reduced the power consumption gap between the two types, making 5-phase motors more energy-efficient than before.

Applications

2-Phase Stepper Motors

2-phase stepper motors are widely used in various applications, including:

- CNC machines: 2-phase motors provide precise positioning for cutting, milling, and engraving operations.

- 3D printers: These motors enable accurate movement of the print head and precise layer-by-layer deposition.

- Robotics: 2-phase motors offer reliable and precise motion control for robotic arms and other robotic systems.

- Automated manufacturing: They are used in assembly lines, material handling systems, and packaging equipment.

5-Phase Stepper Motors

5-phase stepper motors find applications in industries that require higher precision and smoother motion, such as:

- Medical equipment: These motors are used in medical devices that require precise positioning, such as scanning systems and robotic surgical equipment.

- Semiconductor manufacturing: 5-phase motors are ideal for wafer handling and inspection systems, where precise positioning and smooth motion are crucial.

- High-speed automation: They are employed in high-speed pick-and-place machines, PCB assembly systems, and high-speed printing applications.

Conclusion

The choice between a 2-phase and 5-phase stepper motor depends on the specific requirements of the application. While 2-phase motors are more common and offer higher torque at lower speeds, 5-phase motors provide finer step resolutions, smoother motion, and higher speeds.

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00