Which type of servo motor is better in automation equipment?

2024-04-18 17:06:41

Comparison Between AC Servo Motors and DC Servo Motors

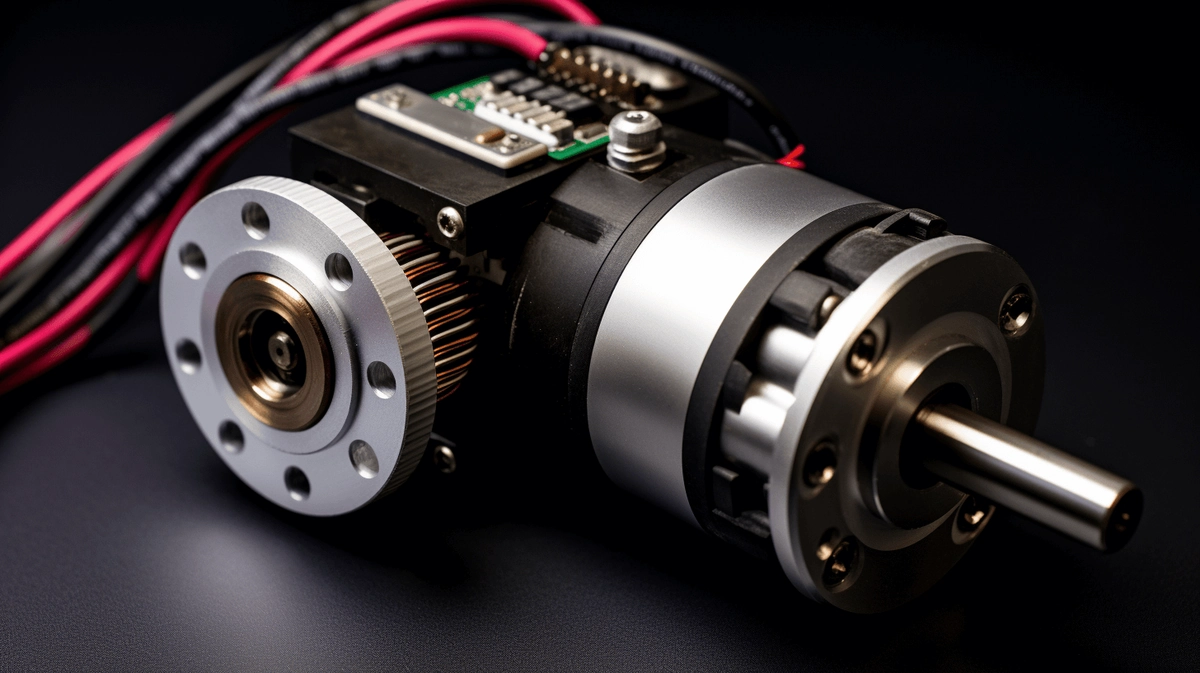

In automated equipment, servo motors are extremely important control motors, but there has always been a debate over the selection of servo motors. Which is better, AC servo motors or DC servo motors? This question is not easy to answer because each has its own advantages. Now let's compare and analyze the differences between them in terms of control accuracy, performance characteristics, and application areas.

DC Servo Motors

DC servo motors are divided into two types: brushed and brushless.

-

Brushed DC servo motors have low cost, simple structure, high starting torque, wide speed range, and relatively easy control. However, brushed motors require maintenance because they use carbon brushes, which wear out over time and need to be replaced regularly. In addition, brushed motors generate electromagnetic interference during operation, requiring higher environmental requirements.

-

Brushless DC servo motors are small in size, light in weight, high in output, fast in response, high in speed, low in inertia, smooth in rotation, and stable in torque. They do not require maintenance, have high efficiency, low operating temperature, low noise, low electromagnetic radiation, and long lifespan. Therefore, DC servo motors are suitable for cost-sensitive general industrial and civilian applications.

AC Servo Motors

The structure of ac servo motor includes stator part and rotor part, commonly used are synchronous and asynchronous types. AC servo motors have good speed control characteristics, can achieve smooth control throughout the speed range, with almost no oscillation. They have advantages such as high efficiency, low heat generation, high precision position control (depending on encoder accuracy), low noise, etc. AC servo motors are suitable for occasions with high requirements for speed, position, and torque control accuracy, such as machine tools, printing equipment, packaging equipment, textile equipment, laser processing equipment, robots, etc. However, the control of AC servo motors is relatively complex, requiring adjustment of the driver's parameters to determine the PID parameters, and more wiring is needed to support its operation.

Choosing the Right Servo Motor

Therefore, both AC servo motors and DC servo motors have their own advantages and characteristics. The choice of which type of servo motor to use depends on specific application requirements. If cost sensitivity and low maintenance requirements are important, DC servo motors can be considered; if high demands on control accuracy, speed range, and noise performance are required, AC servo motors can be chosen. The final decision should be based on actual situations and specific applications.

Considerations in Automated Equipment

In automated equipment, we need to comprehensively consider the performance, cost, reliability, and application requirements of servo motors, choose the appropriate type of servo motor to ensure the efficient operation and precise control of the equipment.

Conclusion

I hope this article will be helpful to you, allowing you to better understand the advantages of AC servo motors and DC servo motors, and choose the right servo motor for your automation application.

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00