How much weight can a servo motor hold?

2023-07-06 17:30:32

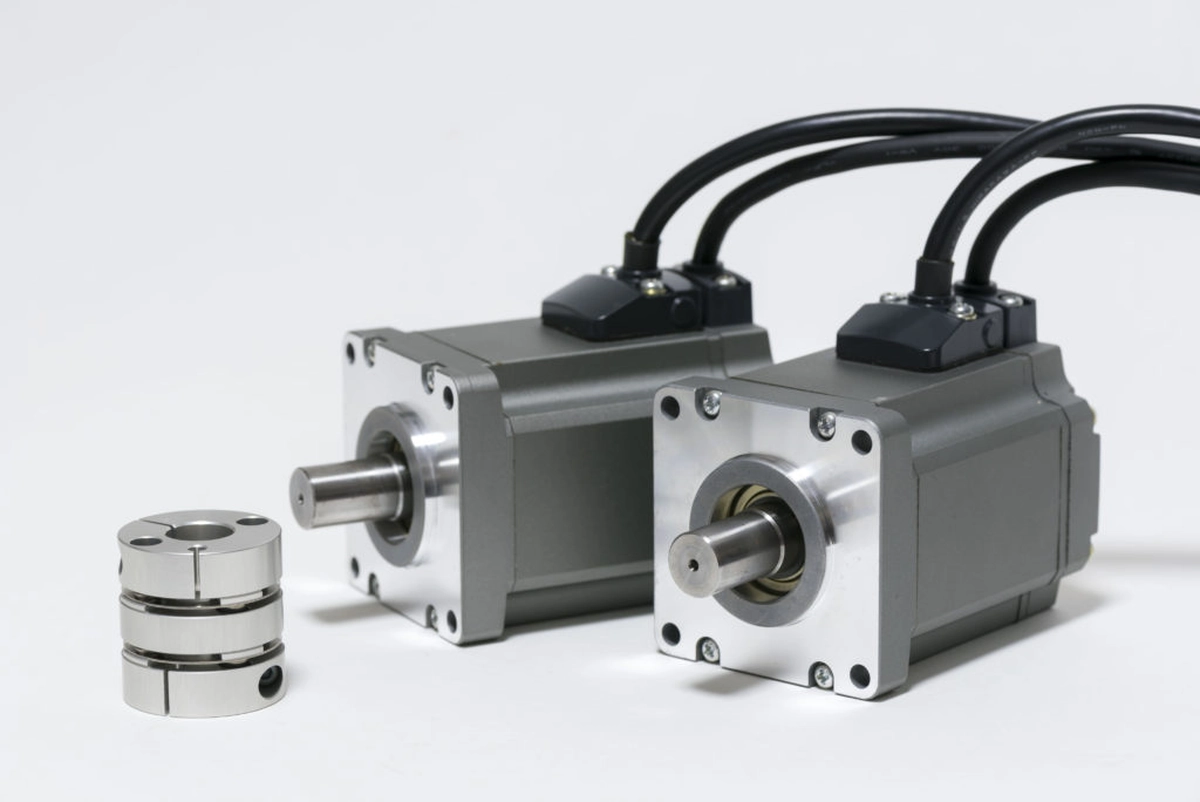

Servo motors are widely used in various applications, from robotics and automation to aerospace and consumer electronics, due to their precise control over position, velocity, and torque. One common question that arises when selecting a servo motor is: how much weight can a servo motor hold? The answer to this question depends on several factors, including the motor's specifications, the mechanical setup, and the application requirements. This article delves into these factors, providing a detailed and technical understanding of how to determine the weight a servo motor can hold.

Understanding Servo Motor Specifications

Torque Ratings

- Stall Torque: The maximum torque the motor can generate when the output shaft is not moving.

- Continuous Torque: The torque the motor can sustain continuously without overheating.

- Peak Torque: The maximum torque the motor can produce for short periods.

Gearbox and Mechanical Advantage

Gear Ratio: The ratio of the input speed to the output speed, which multiplies the torque accordingly. For example, a 10:1 gear ratio increases the torque by ten times.

Motor Power and Speed

The power of the motor, measured in watts (W), and the speed, measured in revolutions per minute (RPM), also play a role in determining the motor's capability to hold weight. Higher power and speed ratings generally indicate a more capable motor.

Duty Cycle

The duty cycle refers to the percentage of time the motor is active versus inactive. Motors designed for continuous operation can hold weight for longer periods, while those with lower duty cycles may only handle weight intermittently.

Calculating the Weight a Servo Motor Can Hold

Step 1: Determine the Required Torque

To calculate the weight a servo motor can hold, start by determining the required torque. This involves understanding the force needed to lift or hold the weight and the distance from the pivot point (lever arm).

Formula: Torque = Force × Distance

For example, if you need to lift a 10 kg weight (approximately 98.1 N) with a lever arm of 0.1 meters, the required torque would be:

Torque = 98.1 N × 0.1 m = 9.81 Nm

Step 2: Consider Gearbox and Efficiency

If the servo motor uses a gearbox, multiply the required torque by the gear ratio. Also, consider the efficiency of the gearbox, typically around 90-95%.

Adjusted Torque:

Adjusted Torque = Required Torque / Gear Ratio × Efficiency

Assuming a 10:1 gear ratio and 90% efficiency, then, the adjusted torque will be 1.09 Nm.

Step 3: Match with Servo Motor Specifications

Compare the adjusted torque with the servo motor's specifications. Ensure the motor's continuous torque rating meets or exceeds the adjusted torque. Also, check the stall and peak torque ratings for short-duration loads.

Step 4: Factor in Safety Margins

Include a safety margin to account for dynamic loads, inaccuracies, and unexpected conditions. A typical safety margin is 20-30%.

Safety Margin:

Required Torque with Safety Margin = Adjusted Torque × (1 + Safety Margin)

Using a 25% safety margin, it will be 1.36 Nm.

Example Calculation

Suppose you have a servo motor with the following specifications:

- Continuous Torque: 2 Nm

- Stall Torque: 3 Nm

- Gear Ratio: 10:1

- Efficiency: 90%

You need to lift a 10 kg weight with a 0.1-meter lever arm. Following the steps:

- Required Torque: 9.81 Nm

- Adjusted Torque: 1.09 Nm

- Required Torque with Safety Margin: 1.36 Nm

The servo motor’s continuous torque (2 Nm) exceeds the required torque with the safety margin (1.36 Nm), indicating it can hold the weight.

Practical Considerations

Load Type

Consider the type of load the servo motor will handle. Static loads are easier to manage than dynamic loads, which involve movement and can cause fluctuating forces. Ensure the motor and mechanical setup can handle dynamic conditions.

Temperature and Environment

Servo motors can generate heat, especially under continuous load. Adequate cooling and ventilation are necessary to prevent overheating. Environmental factors such as dust, moisture, and temperature variations can also affect performance and longevity.

Mechanical Constraints

Ensure the mechanical components, such as the lever arm, bearings, and mounts, are designed to handle the forces involved. Any mechanical weakness can lead to failure, regardless of the motor’s capability.

Feedback and Control

High-precision applications require accurate feedback and control systems. Use encoders, sensors, and control algorithms to monitor and adjust the motor’s performance in real-time, ensuring consistent operation.

Conclusion

Determining how much weight a servo motor can hold involves understanding its torque ratings, considering gear ratios and efficiency, and applying safety margins. By following a systematic approach to calculate the required torque and matching it with the motor’s specifications, you can ensure reliable and precise performance in various applications. Practical considerations such as load type, temperature, environment, and mechanical constraints are equally important to ensure the system’s overall effectiveness and longevity. Servo motors, when selected and implemented correctly, offer robust solutions for a wide range of high-precision and demanding applications.

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00