Sales Case: Servo motor for CNC machining center

2024-01-08 14:17:01

In the rapidly growing industrial sector, the need for high-precision and efficient machining processes has intensified. This is especially true for the machining industry, which is home to a large number of state-of-the-art processing machines that require reliable and precise motion control systems for optimal performance.

Client Background

AkshayDesarda runs a company that manufactures robots that specialize in precision engineering, so every component of the robotic system is scrutinized internally during the manufacturing process. Recently, due to machining requirements, his company needed to purchase several servo motors for machining centers.

Client need

Akshay's requirements were specific: he wanted servo motors that would not only deliver performance but also integrate seamlessly into his machining centers. The key factors he cared about were that integration into the CNC machining center would provide high accuracy, reliable torque, and long-lasting durability. He also emphasized the importance of a waterproof design and a high degree of protection for the motors to prevent any damage caused by the ingress of dust or liquids.

Our customized solutions

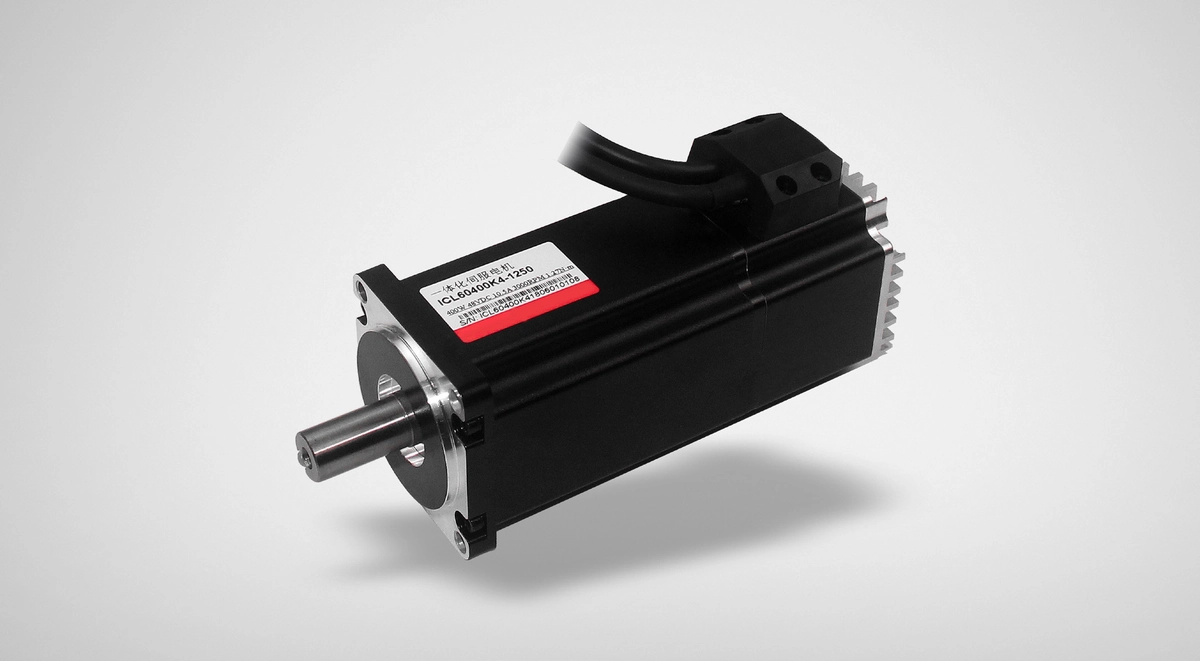

To meet AkshayDesarda's stringent requirements, we recommended a servo motor equipped with a specialized drive running at 60Hz. The motor has been carefully designed with an IP67 protection rating to ensure that it can withstand the exposure to coolant and metal shavings typical of a CNC environment. The rated torque of 9.55Nm ensures the precision and strength required for complex machining tasks. A fan cooling system fitted to the motor helps to maintain optimum operating temperatures over long periods of working conditions, thus extending the life of the motor. Finally, the 130mm flange facilitates easy mounting in keeping with the mechanical interface of the Akshay machining center.

Client testimonials and impact

After the integration, Akshay noticed a significant improvement in the performance of his CNC machining center compared to before. The precision and robustness of the servo motors translated into higher-quality output that ran well.

Challenge

During the initial phase of communication with Akshay, we encountered some challenges in aligning our technical proposal with his specific requirements. However, we quickly resolved the issue by organizing a detailed discussion and thoroughly explaining the features and benefits of our proposed solution. By actively listening to Akshay's concerns and clarifying any doubts, we established a strong rapport and built trust, resulting in a mutually satisfactory agreement.

See What Lunyee Can Do For You

Contact Us

- 8619149417743

- +86-0371-5562 0274

- [email protected]

- Zhengzhou, Henan Province, China

- Mon-Fri: 9:00 - 18:00